1. Introduction

asalt is a type of igneous rock formed by the rapid cooling of lava at the surface of a planet. It is the most common rock in the Earth's crust. Basalt rock characteristics vary from the source of lava, cooling rate, and historical exposure to the elements. High quality fibres are made from basalt deposits with uniform chemical makeup. The production of basalt and glass fibers are similar. Crushed basalt rock is the only raw material required for manufacturing the fiber. It is a continuous fiber produced through igneous basalt rock melt drawing at about 2,700° F (1,500° C). Though the temperature required to produce fibers from basalt is higher than glass, it is reported by some researchers that production of basalt fiber requires less energy by due to the uniformity of its heating. In addition to high specific strength, high specific modulus, BCF(Basalt concrete fibre) also has excellent temperature resistance (-260~700_), anti-oxidation, anti-radiation, thermal and sound Insulation, filtration, anticompression strength and high shear strength, high availability, and good cost performance. It is found in nature as an inorganic non-metal material, and is a new basic material and high-tech fibre that can satisfy the demand for the development of basic infrastructures.

Basalt fibre is a "multi-performance" fibre. For example, it is resistant to alkalis and acids; it is Author : Professor and HOD, Doctor of Science (D.Sc) scholar, Department of Civil Enginnering, Dr.M.G.R Educational and Research Institute University, Chennai, Tamil Nadu, India. E-mail : [email protected] thermally, electrically and sound Insulated; its tensile strength can be greater than large-tow carbon fibre, its elongation is better than small carbon fibre. Basalt has a 3-dimentional molecule and when compared with single infiltrating linear polymeric fibres. It is cost effectiveness, anti-aging, as well as other excellent Characteristics. Basalt fibre for cement and concrete is not expensive, it is a competitive alternative product of poly propylene fibre and polyacrylonitrile fibre. Basalt fibre is a typical ceramic fibre, it's easy to disperse when mixed with cement concrete and mortar. Therefore, basalt fibre reinforced concrete serves the functions of reinforcement, crack resistance, and can extend the life of construction in the fields of housing, bridges, Highways, railways, urban elevated roads, runways, ports, subway tunnels, the coastal Protection works, plant facilities. Banthia et al(2005)Performance of conventional Concrete is enhanced by the addition of fibres in concrete. The brittleness in concrete is reduced and the adequate ductility of concrete is ensured by the addition of fibres in concrete. In this paper the behaviour of RC beam structures strengthened by using hybrid fibre reinforced concrete (HFRC) is analyzed. Mattys et al(2005) experienced BFRP(basalt fibre reinforced polymer) is a new material in civil engineering compared to carbon, glass and aramid and has shown to be a promising material for infrastructure strengthening. They are made from basalt rocks through melting process and contain no other additives in the producing process which makes advantages in cost. Basalt fibres show comparable mechanical properties to glass fibres at lower cost and exhibit good resistance to chemical and high temperature exposure. Aggarwal et al(2007) presents the experimental investigations carried out to study the effect of use of bottom ash as a replacement of fine aggregates. The various strength properties studied consist of compressive strength, flexural strength and splitting tensile strength. The strength development for various percentages (0-50%) replacement of fine aggregates with bottom ash. Singaravadivelan et al (2012) conducted research is currently Basalt fiber reinforced polymer, is the (BFRP) application is very effective ways to repair and strengthen structures that have become structurally B repair systems and materials. Experimental investigations of the cube, cylinder & flexural RC beams strengthened using basalt fiber unidirectional cloth is carried out. From the experiments it was found that Wrapping the concrete cube and cylinder specimen to 25%increase the strength compared to controlled specimens. The flexural strength of the element of the strengthened RC beams increases significantly after strengthening with BFRP cloth. There is little research concerning the application of basalt fibre in civil engineering and its strengthening efficiency on concrete elements. This paper presents the tests that were performed on BFC (Basalt fibre concrete) cubes and cylinder specimens under concentric compression loading and split tensile test.

2. II.

3. Experimental Programme

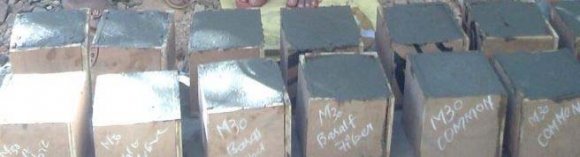

The main objectives of the experimental program were (a) to investigate the effectiveness of confinement based on the basalt fibers preimpregnated and bonded with concrete (b) to compare the performance (in terms of strength)of different confinement techniques. This investigation was carried out on concrete16nos.cubes, (150mm x150mm x150mm) for finding compressive strength, 18 n a) Selection of raw materials os. cylinder (150mm x300mm) for compression as well as split tensile test. Each specimen was casted as per IS procedure. After casting the test M-20 and M-30 grade concrete specimen were demoulded and specimens were kept for a period of 7 days, 14 days and 28 days in the curing tank until the time of test. Detailed mix ratio of each grade of concrete is given in Table 1.Figure 1 and Figure 2 shows the test specimen of concrete cubes. The thermo and Physical properties of the Basalt fibres are given in Table 2 and Table 3.

4. i. Cement

The ordinary Portland cement was classified into three Grades, namely 33 grades,44 grades and 53 grades depending upon the strength of cement at 28 days when tested as per IS4031-1988.If 28days strength is not less than 53 N/mm 2 , it is called 53 grade cement. In this research M20 and M30 grade cement is selected for the study, coramandal king 53 grade(OPC) cement has been used for this research.

ii. Fine Aggregate Natural river sand with fraction passing through 4.75 mm sieve and retained on 60 micron sieve is used and will be tested as per IS 2386. The fineness modulus of sand is 3.08 with specific gravity around 2.65.

5. iii. Coarse aggregate

Coarse aggregates of maximum sizes 20 mm, 16mm and 12.5mm and the compressive strength were obtained for maximum size of coarse aggregate. From that it was concluded that compressive strength using 12.5 mm aggregates gave the best result and it will be useful for our study. The physical properties will be tested as per IS 2386-1963.

6. iv. Water

Portable water available in the laboratory with pH value of 7.0 and conforming to the requirement of IS 456 -2000 is used for making the concrete and curing the specimen as well. Compression strength of concrete with and without basalt was conducted. The compression test was conducted as per IS 516 -1959. The specimens were kept in water for curing for 7 days, 14 days and 28 days and on removal were tested in dry condition and grit present on the surface. The load was applied without shock and increased continuously at a rate of approximately 140 kg/sq cm/min until the resistance of the specimen to the increasing load breaks down and no greater load can be sustained. The maximum load applied to the specimen was then recorded and the appearance of the concrete for any unusual features in the type of failure was noted. Average of three values was taken as the representatives of the compressive strength of the sample as noted. Result are shown in above Table 4.

7. ii. Splitting Tensile Test

The split tensile test were conducted as per IS 5816:1999. The size of cylinder is 300mm length with 150mm diameter. The specimen were kept in water for curing for 7 days, 14 days and 28 days and on removal were tested in wet condition by wiping water and grit present on the surface. The test is carried out by placing a cylindrical specimen horizontally between the loading surfaces of a compression testing machine and the load is applied until failure of the cylinder along the vertical diameter. The maximum load applied to the specimen was then recorded and the appearance of the concrete for any unusual features in the type of failure was noted. Average of three values was taken as the representative of batch. The test is carried out by placing a cylindrical specimen horizontally between the loading surfaces of a compression testing machine and the load is applied until failure of the cylinder along the vertical diameter.

To find split tensile strength following equation has used. Figure 3 Result And Discussion

8. a) Compression Test

Compressive strength of concrete mixes made with and without basalt fibre was determined at 7, 14 and 28 days. The test results are given in Table 4 and Figures 4 and Figure 5.The gain of strength of basalt fibre concrete with respect to their compressive strength at the age of 7 days was 20%-24% of M20 and M30 grade of basalt concrete when compared to same grade of controlled concrete. In 19%-29% at 14 days of M20 and M30 grade of basalt concrete when compared to same grade of controlled concrete. Also 23%-25% varies at 28 days of of M20 and M30 grade of basalt concrete when compared to same grade of controlled concrete. The basalt concrete gains strength at a beginning stage onwards and acquires strength at faster rate due to pozzolanic action of basalt fibre. Therefore, the ultimate strength were taken at the peak load which was considered to represent the material strength of the BFC(Besalt fibre concrete). Figure shows the gradual and good increase of compressive strength of basalt concrete when compared to controlled concrete cubes. These results review the efficiency of BF concrete as a strengthening material for concrete columns but as this paper only presents tests on small concrete specimens like cubes and cyliners, further research needs to be done on reinforced columns of different cross sections.

9. Conclusion

From the research following conclusions were obtained Compressive strength and Splitting tensile strength of basalt fibre concrete specimens were higher than control concrete specimens at all the ages.

Compressive strength of basalt fibre concrete containing 40% basalt fibre is acceptable for most structural applications since the observed compressive strength is more than 20 MPa at 28 days for M20 and M30 grade control concrete. So basalt enables the large utilization of basalt fibre in concrete.

The strength difference between basalt fibre concrete specimens and control concrete specimens became high distinct in the beginning age of curing itself.

M 20 and M30 grade basalt fibre concrete at 28 days strength attains the compressive strength equivalent to 120% and 123% and attains splitting tensile strength in the range of 123-125% at 28 days of flexural strength of control concrete at 28 days.

From the research it was proposed that, the usage of Basalt fibers in low cost composites for civil infrastructure applications gives good mechanical

| weak over their life of the span. BFRP Repair systems | |||||

| provide an economically viable alternative to traditional | |||||

| ear 2012 | |||||

| Y | |||||

| ( E ) | |||||

| Grade of Cement | Cement | Sand(Kg) | Water(litres) | 20 mm(Kg) | Basalt fibre(gm) |

| (kg) | |||||

| Mix ratio for M20 grade concrete cube | |||||

| Normal concrete | 12.74 | 18.711 | 4.116 | 37.22 | Nil |

| Basalt concrete | 12.74 | 18.711 | 4.116 | 37.22 | 29.7 |

| Mix ratio for M30 grade concrete cube | |||||

| Normal concrete | 11.286kg | 21.104kg | 4.75litres | 38.101kg | nil |

| Basalt concrete | 11.286kg | 21.104kg | 4.75litres | 38.101kg | 29.7mg |

| Mix ratio for M20 grade concrete cylinder | |||||

| Normal concrete | 6.678 | 10.017 | 2.226 | 20.03 | Nil |

| Basalt concrete | 6.678 | 10.017 | 2.226 | 20.03 | 15.9 |

| Mix ratio for M30 grade concrete cylinder | |||||

| Normal concrete | 6.042 | 11.309 | 2.544 | 20.44 | Nil |

| Basalt concrete | 6.042 | 11.309 | 2.544 | 20.44 | 15.9 |

| grade strength respectively All cylinders show a good | ||||||

| ductile behavior. | ||||||

| ear 2012 | ||||||

| Y | ||||||

| Sl. no | M 20 Grade concrete | Sl. no | M 30 Grade concrete | |||

| 26 | Normal concrete | Basalt Concrete | Normal concrete | Basalt Concrete | ||

| Global Journal Volume XII Issue IV Version I E ) ( of Researches in Engineering | 7 th day 14 th day 28 th day | 16.02 N/mm 2 18.75 N/mm 2 21.33 N/mm 2 30 10 20 25 IN N/mm 2 15 STRENGTH 5 0 40 0 5 45 10 15 20 25 30 35 STRENGTH IN N/mm 2 | 19.273 N/mm 2 22.335 N/mm 2 27.530 N/mm 2 | 7 th day 14 th day 28 th day | 22.013 N/mm 2 25.257 N/mm 2 32.875 N/mm 2 FOR CUBE IN 28 DAYS COMPRESSIVE STRENGTH FOR CUBE IN 7 DAYS COMPRESSIVE STRENGTH FOR CUBE IN 14 DAYS COMPRESSIVE STRENGTH FOR CUBE IN 28 DAYS COMPRESSIV E STRENGTH FOR CUBE IN 7 DAYS E STRENGTH FOR CUBE IN 14 DAYS COMPRESSIV E STRENGTH COMPRESSIV | 27.35 N/mm 2 35.730 N/mm 2 40.357 N/mm 2 |

| b) Splitting Tensile Test | 25% split tensile strength at 7 days when compared to | |||||

| The results of splitting tensile strength of | controlled concrete of M20and M30 grade. As 39% & | |||||

| concrete mixes with and without basalt fibre measured | 45% split tensile strength at 14 days when compared to | |||||

| at 7, 14 and 28 days are given in Table 5 and shown in | controlled concrete of M20and M30 grade strength | |||||

| Figures 6 and Figure 7. Figures shows the variation of | whereas 37% & 47% of split tensile strength at 28 days | |||||

| splitting tensile strength. Basalt concrete attains 35% & | when compared to controlled concrete of M20and M30 | |||||

| © 2012 Global Journals Inc. (US) | ||||||

| Sl.no | M20 Grade Concrete | SL.NO | M30 Grade Concrete | ||

| Normal concrete Basalt Concrete | Normal concrete Basalt Concrete | ||||

| 7 th day | 1.708 N/mm 2 | 2.820 N/mm 2 | 7 th day | 2.551 N/mm 2 | 4.477 N/mm 2 |

| 14 th day | 1.944 N/mm 2 | 3.183 N/mm 2 | 14 th day | 2.641 N/mm 2 | 4.576 N/mm 2 |

| 28 th day | 2.137 N/mm 2 | 3.376 N/mm 2 | 28 th day | 2.806 N/mm 2 | 5.250N/mm 2 |