1. INTRODUCTION

he phenomenon of the vibration of the cutting tools is a main issue which appears during the process of cut of metals. This problem with an influence very import on the qualitative level such as tolerances of manufacture, surface quality?.Several studies were presented. Bourdim et al [1] illustrates an approach of the study of the dynamic stability of the system part-tool in the course of machining .In work of (Arfaoui et al ) (Bourdim et al ) ( Wu D.W., Liu C.R ) [2,3,4], the authors present a vibratory modeling of the cutting tool in turning, they showed that the vibratory be havior of the tool depends primarily on the angle of attack, angle strip, advance, depth of cut and the cutting speed . the work of Younes R. [5] a study was carried out on the influence cutting speed on the vibrations of chattering of the tool with an aim of proposing an analytical study by analogy with the model of Vander pole. The work of N. Ouelaa et al [6] presents an experimental semi study of the vibratory behavior of the cutting tool golds of the operation of slide-lathing, fact object of showing that it is possible to consider the roughness average of the part machined starting from displacement resulting from the nozzle of the tool and for the work of Vincent et al [7] a study was presented on the influence of the position of the tool on dynamic behavior in milling of thin walls.

In the last 20 years, the p-version finite element method has generated a lot of interest [8,9]. The main reason for this interest is the remarkable convergence properties that the method has [10].The p version gets these convergence properties from the fact that it converges to the solution by increasing the order of element shape functions instead of increasing the number of elements as the h -version finite element approach does.

In our work a theoretical study on the vibrations of the cutting tools by the finite element method which makes it possible to choose a good system design starting from the Eigen frequencies.

2. II.

3. VIBRATORY BEHAVIOR OF THE CUTTING TOOL MODELING

In general, we can consider that a structure or an element of structure will be of beam type if one of its dimensions (length) is large in front of the two others. The experiments [11] watch which we can make a known simplifying assumption under the name of assumption of Bernoulli-Euler who expresses himself as follows:

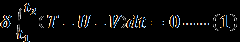

"Any normal plane section with average fiber before deformation remains plane and normal with this average fiber after deformation (effect of null shearing)" [11,13].In our case, we can modelize the cutting tool by a beam Clamped-Free (Figure1).

? ? ? ? ? ? ? ? ? 0 ) , , ( ) ( ) , , ( ) ( ) , , ( 0 0 z y x W x V z y x V y x U z y x U ? (1) ) 0 , 0 , ( ) ( 0 x U x U ? ) 0 , 0 , ( ) ( 0 x V x V ? ? y ?There: Position of a point M of the cross-section.

4. b) Deformation tensor

The components ij of the te ns or of deformation are given by the relation (2): ? For we have the matrix (3) following:

In the form of the tensor, while noting: : it is the generalized relative deformation of the average line.

: it is the shearing strain.

: it is the curve of the a ve ra g e line , with ra d ius of the curvature.

5. c) Shearing assumption

In the majority of the cases, the deflections longitudinal, corresponding has due to the traction and compression and/or with the bending, are definitely more important than the deformations due to shearing. Noun let us can thus very often neglect the deformations due to shearing in the case of the long beams (L/h>20).

Therefore, by supposing the following relation is obtained:

Lead: d) Stress Deformations RelationsThe relation ( 9) is obtained starting from the generalization of the law of Hooke:

6. e) Deformation energy

The deformation energy of the system, equation (10), it is the sum of deformation energies of each element.

The general form of the deformation energy will be given by the relation (11):

f) Kinetic energyThe kinetic energy of the system, equation (12), it is the kinetic sum of energy of each element:

The kinetic energy of an element moving, formula (13), it is the sum of the energy of the beam and the energy of the mass of the Mj engine: With EcP : Kinetic energy of the beam, equation ( 14). EcMj : Kinetic energy of the concentrated mass equation (15).

28 Global ( A ) 2011 December 3 , 2 , 1 , ) ( 2 1 ? ? ? ? ? ? ? j i x U x U i j j i ij ? (2) ? xx , ? xy , ? yy ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? 0 ) ( 2 1 ) ( 2 1 0 0 0 ? ? ? ? x V x V x y x U (3) -0 ? x U ? ? ? 0 0 ? (4) -? ? ? ? ? ? ? x V 0 (5) ? - ? ??? ? ? ? 1 ? ? ? ? x (6) xx ? ? ? systematically, =0 0 0 ? ? ? ? ? x V ==> ? 0 ? ? ? x V (7) ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? 0 0 0 2 0 2 0 x V y x U ? (8) ? ? . D ? (9) ? ? ? ? n e e U U 1 (10) ? ? V ij ij e d U v . 2 1 ? ? (11) ? ? ? ? n e e Ec E 1 (12) J M p e Ec Ec Ec ? ? (13) ) 2 ( 2 1 v ) ( 2 2 1 v . ) ( 2 2 1 v . . . 2 1 v . . . 2 2 1 v . . 2 1 . . . . . . . . . 2 dv x x x A r r r d x r A h d x r A h d h h d h h d h h Ec T T T i v i T i v i T T T v i T v T v T v T P T ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? (14) ] ) 2 ( ) (2) ( 2 . . . . 2 [ M 2 1 . . . . . . . . . 2 j l x T T T i i T i i T T i T T T T T T M x x x A r r r x r A h x r A h h h h h h h Ec J ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? (15)7. g) Motion equations

The equations of Lagrange make it possible to obtain the equations of the movement of an element of the structure (element beam with mass concentrated at the end) starting from the expression of the kinetic and potential energy elementary, equation (16).

U Ec t q q L i i ) , , ( . ? ? (16) III.8. FORMULATION BY THE FINITE ELEMENT METHOD HIERARCHICAL

The particular characteristic of the finite element method is that the field, in which an approximate solution is required is divided into under field called finite elements. The unknown quantity, such as displacement is represented in each element by polynomial functions simple. Its functions are called elementary functions of forms.

For a given formulation the choice of the subdivision (mesh) and functions of forms determines the precision of the approximation. The cutting tool is modelized by only one element, called hierarchical finite element, the field of displacement describe the element is given by (17): With: P: Many functions of form.

9. Such as:

The components of the vector {E} necessary to the determination of rigidity are given in the system of coordinates Cartesian, relation (18).

10. With:

The vector of deformation {E} is given according to {Q} in the matrix form (19) following: With: a) Energy in the matrix form

The kinetic energy and of elementary deformation in the matrix form is given by the relation (20):

? ? ? ? e e q N V U ? ? ? ? ? ? ? (17) ? ? ? ? P n Y Y X X q T p p T ,..., 1 . ... , ... 1 1 ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? v 0 0 N N N u e ? ? ? ? ? ? ? ? ) ( )... ( ), ( ) ( )... ( ), ( 2 1 v 2 1 u ? ? ? ? ? ? P P g g g N f f f N ? ? ? ? ? ? ? ? ? ? ? ? ? V U A e e (18) ? ? ? ? ? ? ? ? ? ? ? ? ? ? 2 2 1 ? ? L y L A e ? ? ? ? ? ? ? ? ? ? ? ? ? ? q B e q N A e e e e ? ? (19) ? ? ? ? ? ? e e e N A B ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? 1 0 1 0 1 0 ) 2 ( 2 1 ) ( 2 2 1 ) ( 2 2 1 . . . . . . ? ? ? ? ? ? d x x x A r r r L S d x r A N q L S d x r A N q L S T T T i i T i i T T T i T T T T ? ? ? ? ? ? ? ?? ? ? ? ? ? ? ?? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? 1 0 2 1 0 1 0 2 1 2 2 1 2 1 . . . ? ? ? ? ? ? d q N N q L S d q N N q L S d q N N q L S Ec T T T T T T p (20)The kinetic energy of the mass is given in the matrix form by the relation (21):

? ? ? ? ? ? ? ?? ? ? ? ? ? ? ?? ? ? ? ? ? ? ? ? ? ? ? ? ? ) 2 2 2 2 2 ( . . . . . . . . . 2 1 i T T T T T T T T i T T T T T T T T T T T T j M r A N q r r l N q r A N q l N q q N N q q N N q q N N q M Ec J ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? (21)The relation ( 22) presents the deformation energy in the matrix form.

? ? ? ? ? ?? ? ? ? ? ? ? ?? ? ? ? ? ? 1 0 , v , v T 3 1 0 , , T 2 1 2 1 ? ? ?? ?? ? ? d q N N q L I E d q N N q L S E U T u T u e (22)The equations of Lagrange are written in the matrix form, equation (23).

? ? ? ? ? ? ? ? ? ? ? ?? ? ? ? ? ? ext e e e e e F r q P R K q G q M . .. ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? (23)The matrix of rigidity is given by (24):

? ? ? ? ? ? ? ? V T e dV Be Be E K (24)The centrifugal matrix of rigidification is given par. The matrix of rigidification of angular acceleration [P] is given by: By identification.

? ? ? ? ? ? ? ? 1 0 2 3 ? ? ? d N N L S R T P (25) ? ? ? ? ? ? ) 1 ( ) 1 ( 2 3 N N M R T j M J ? ? (26)According to the kinetic energy, the gyroscopic matrix is given by:

? ? ? ? ? ? ? ? ? ? 1 0 ? ? d N N L S P T P (28) ? ? ? ? ? ? T T j M N N M P J ) 1 ( ) 1 ( ? ? ? (29)According to the kinetic energy the matrix mass is given by -Clamped-Free Beam: In the represented by Figure 3, in the case of give the variation of the first three parameters of frequency according to the number of hierarchical modes NMH a clamped-free beam (C-F), we notice that convergence is ensured starting from a number of modes equal to 8.

? ? ? ? ? ? J M P M M M ? ? (30) ? ? ? ? ? ? ? ? 1 0 P ? ? d N N L S M T (31) ? ? ? ? ? ? ) 1 ( ) 1 ( J M N N M M T j ? (32) ? ? ? ? ? ? J M p G G G ? ? (33) ? ? ? ? ? ? ? ? ? 1 0 2 ? ? d N N L S G T p (34) ? ? ? ? ? ? ) 1 ( ) 1 ( 2 N N M G T j M J ? ?(11. C. Influence speed on the va lues of the puls a tions :

The variation of the parameters of pulsation of the first four modes for variations rotational speeds are given by table 2.

12. CONCLUSION

In this work, a modeling of the cutting tool by the hierarchical finite element method was the object to determine the Eigen frequencies. The latter has an important influence on the tolerances of manufacture and the surface quality. The found results ensure convergence in the stationary case (rest) and moving, the compared errors are almost the same ones with [13] In all the cases, the Eigen frequencies vary almost linearly in the beach of [0,10] and increases with the increase rotational speed. These frequencies enabled us to pose a good design of system of assembly of the cutting tool .

| a beam (C-F): |