1.

Abstract-Through the decades, the price of aluminum has been accumulative due to economic influences globally. In spite of it, people still incline to overlook the fact that the aluminum scrap thrown away is recyclable and beneficial. Hence, the authors came up with an idea to create a machine that will serve as a recycle bin. Through problems identification, the objectives were identified as guides in the establishment of "Aluminum Can to WiFi Trading System with Metal Can and Plastic Bottle Collector and Monitoring System" for the school. This machine is designed having a ramp and dimension that serves as the pathway of the collected metal cans and plastic bottles and houses a bin designated for each material. It is equipped with ultrasonic, inductive, and infrared sensor to sort, monitor, and count the metal cans and plastic bottles. It displays information, terms and condition, and transaction through the TFT LCD screen with three push buttons as its user input. It was installed with an Access Point that serves as the Network Address Translator to provide internet access to the user. This paper is about a microcontroller based project, with microelectronics devices namely, Ultrasonic Sensor (HCSR04), TFT LCD Display (MD070SD), IR proximity sensor, NPN Inductive Sensor LJ12A3-4-Z/BX NPN, a MG996R Servo and SG90 Micro Servo, ESP8266 node MCU, Arduino MEGA and push button. These were carefully programmed and patiently tested to ensure its working conditions. Through well-planned design, data gathering and testing its reliability, the authors came up with an aluminum can trading system in a robotic application with features like Access Point, monitoring system and sorting metal cans and plastic bottles. The authors concluded that this project is reliable and can help the school in managing the plastic bottles and metal cans used by the students.

2. I.

Introduction he problems of waste generation and management have become a severe issue of concern to lots of the scholars in environmental studies [1]. There are a lot of human activities that donate to waste generation and these waste materials if unsuccessful to be predisposed in the proper manner and in the proper place it will produce a serious complication to humans and threat to nature [8]. As the world becomes more industrial and technologically advanced consumption rates are on the rise and a certain value of more consumption is the rapid increase Author ? ? ? ? ¥ §: College of Engineering, AMA Computer College, Santiago City, Isabela, Philippines. e-mail: [email protected] in the amount of waste that is produced [10]. Recycling is one of the most important actions currently available to reduce these impacts and represents one of the most dynamic areas in the industry today [2].

Through this, the authors come up with a sorting bin application intended for metal can and plastic bottle collection that can detect and sort object with monitoring system composed of LED and push button, a node MCU for notification and access point and servos to sort the metal cans and plastic bottles. The combination of these functions makes the authors challenged to establish a research that can help our environment.

3. II.

4. Experimental Methods a) General System Design

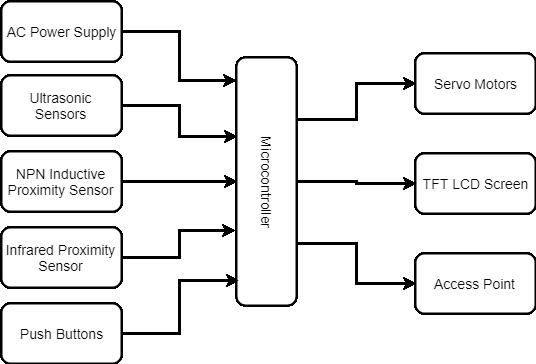

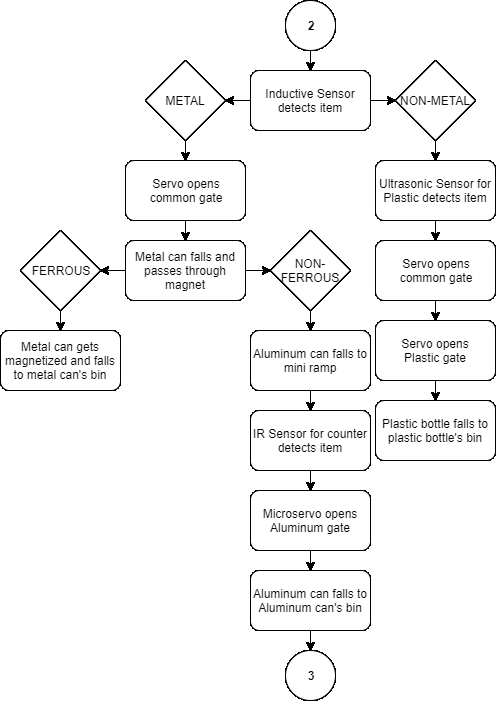

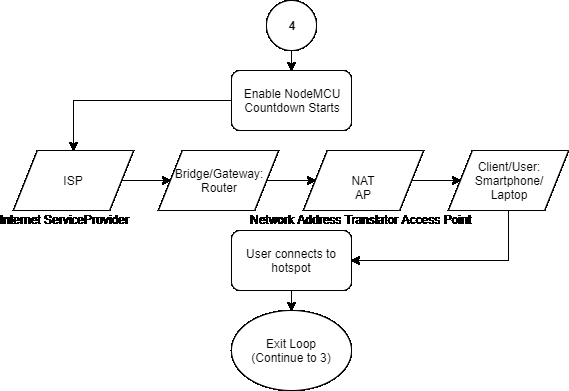

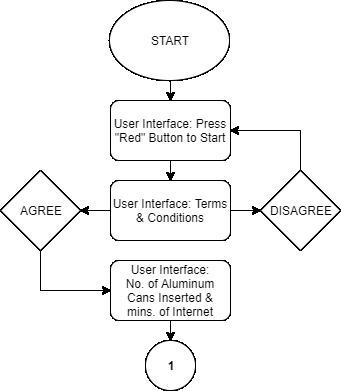

The general concept of this paper is illustrated through figure 1. These figures are the system architectures that explains the functionalities of the Aluminum Can to WiFi Trading System with Metal Can and Plastic Bottle Collector and Monitoring System. Figure 1 is the diagram that shows the left side as the inputs and the right side as the output while the microcontroller acts as the main controller of the device. operates. It is equipped with sensors capable of detecting 3 major inputs which are plastic bottle, tin can, and aluminum can. The inductive sensor that triggers the sorting system of the machine. The ultrasonic sensor detects the cans and bottles allowing the machine to guide them using the servos. Infrared sensor counts the aluminum can. Finally, the LCD will display the SSID, password and time. Then the user will access the internet through Access Point. The wiring diagram of its circuitry is shown in figure 3.1 and 3.2. It illustrates as a guide in connecting each of the components used for the project. In figure 3.1, the main device used is the Arduino Mega microcontroller that serves as the brain of all the components connected. The infrared sensor, inductive sensor, and ultrasonic sensor serves as the input sensors which triggers different operations and activate other devices like servo which will guide the inputs to the bin, LCD that will display the information and transaction, and the Access Point that will provide the user internet access. In figure 3.2, the ultrasonic sensors serve as counters that send data to the Access Point.

5. Results and Discussion

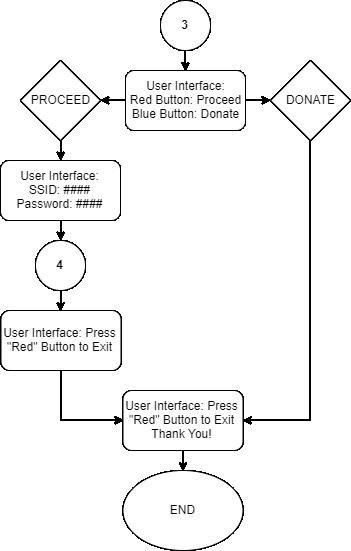

One important phase in establishing this paper is the testing the functionalities of the prototype or the robot itself. It was put into several tests to come up with a desirable output. Tests include unit testing, acceptance testing and integration testing. Unit testing was established to assess all the components used and make sure that all are functioning. Acceptance and integration testing guaranteed that all runs according to its objectives. Detailed tests in the given next tables which showed the reliability of the robot. Ultrasonic and inductive sensor segregation test was also established to determine the sorting function of the machine. Table 2 shows the result of ultrasonic and inductive sensor segregation test made by the authors. The number of trials given in the table are just samples extracted from several trials made by the authors. There are 3 trials with plastic bottle, 3 trials with tin can and 4 trials with aluminum can collected. In here, it shows that when there is a plastic bottle, both servo will open. However, if the material is tin can or aluminum can, only the first servo will open. Also, the inductive sensor can't detect the plastic bottle. Hence, the table has proven the good performance of segregation according to its desired function. The Access Point time limit test shows that the access point will only turn off when there is no remaining time left. The remaining time is displayed on the LCD while the access point runs when the user as accessed the internet. 4 shows the access point distance limit test to determine the range of the device. It shows that the access point shuts down when the user is disconnected. It also shows that the maximum range of the access point is 10 meters. Figure 4 shows the final design output of the Aluminum Can to WiFi Trading System with Metal Can and Plastic Bottle Collector and Monitoring System. It also shows the labeled location of every component integrated inside. The device will work if it is turned on using the AC found at the back of the device. Every labeled component has its own functions. Its main body is made up of plywood and glass for protection of the electronic components. Inside the casing are the devices used such as ultrasonic sensor, infrared sensor, inductive sensor, node MCU, TFT LCD, push button, servo, and three bins as storage for aluminum can, tin can, and plastic bottle.

IV.

6. Conclusion

This paper presented the specifics of the structure of the device as well as the details of the experimental data showing the desired outputs of the device. The components used in this project includes sensors that could detect plastic bottles, tin cans, and aluminum cans. It is stationary and runs on AC.

The project was made possible through different processes and steps and studies addressing the university staff's problems in collecting and segregating plastic bottles, metal cans, and aluminum cans. The project was proven working with its intended function. The researchers concluded that this project is working and is proven effective. This project can deal with plastic bottles, metal can and aluminum can management.

| ersion I |

| Trial | Material | Inductive Status | Ultrasonic Status | Servo1 Status | Servo2 Status |

| 1 | Plastic Bottle | UNDETECTED | DETECTED | OPEN | OPEN |

| 2 | Plastic Bottle | UNDETECTED | DETECTED | OPEN | OPEN |

| 3 | Plastic Bottle | UNDETECTED | DETECTED | OPEN | OPEN |

| 4 | Tin Can | DETECTED | DETECTED | OPEN | CLOSED |

| 5 | Tin Can | DETECTED | DETECTED | OPEN | CLOSED |

| 6 | Tin Can | DETECTED | DETECTED | OPEN | CLOSED |

| 7 | Aluminum Can | DETECTED | DETECTED | OPEN | CLOSED |

| 8 | Aluminum Can | DETECTED | DETECTED | OPEN | CLOSED |

| 9 | Aluminum Can | DETECTED | DETECTED | OPEN | CLOSED |

| 10 | Aluminum Can | DETECTED | DETECTED | OPEN | CLOSED |

| Trial | Remaining Time | Access Point Status |

| 1 | 45 mins | RUNNING |

| 2 | 40 mins | RUNNING |

| 3 | 35 mins | RUNNING |

| 4 | 30 mins | RUNNING |

| 5 | 25 mins | RUNNING |

| 6 | 20 mins | RUNNING |

| 7 | 15 mins | RUNNING |

| 8 | 10 mins | RUNNING |

| 9 | 5 mins | RUNNING |

| 10 | 0 min | OFF |

| Trial | Distance | Phone Status | Access Point Status |

| 1 | 3 meters | CONNECTED | RUNNING |

| 2 | 4 meters | CONNECTED | RUNNING |

| 3 | 5 meters | CONNECTED | RUNNING |

| 4 | 6 meters | CONNECTED | RUNNING |

| 5 | 7 meters | CONNECTED | RUNNING |

| 6 | 8 meters | CONNECTED | RUNNING |

| 7 | 9 meters | CONNECTED | RUNNING |

| 8 | 10 meters | CONNECTED | RUNNING |

| 9 | 11 meters | DISCONNECTED | OFF |

| 10 | 12 meters | DISCONNECTED | OFF |