1. Introduction

uring the later part of the 20th century, the clothing and textile industries of many developed and developing countries have changed dramatically. The Textile & fashion industry is highly complex, with some of the longest and most complicated pipelines of the manufacturing sector [1][2][3][4][5][6].

No longer are clothes manufactured and retailed in specific local regions. Fashion and clothing have joined textiles in becoming a truly global operation with many manufacturing functions blurring [3,5,7,8]. In the past, the clothing industry has only two-season cycle (summer and winter collections).

As consumers became more fashion aware, the clothing industry responded in adding two more season, spring and autumn collections. Nowadays increased collection ascended to six and eight collections a year and even some companies have more; for example, Calvin Klein has ten collections within a year [9]. Fashion today has accelerated; retailers have moved from seasonal collections to offering new merchandise on an ongoing basis. The trend towards smaller orders in a variety of styles and colors, combined with shorter-than-ever lead times, has become the industry norm. To reestablish a competitive position in the international marketplace, the apparel industry is focusing on upgrading its responsiveness to customer needs. Smaller orders are placed in a more dynamic fashion, forcing the efficient production of smaller lots. Like other business, apparel factory is set for profit generation. Profit can be improved by saving from each cost factors of garment making. Fabric is the most important part of a garment, and it represents around 60-70% of total product manufacturing cost. Fabric cost of a product depends on how much fabric is consumed to make the garment, including cut wastes and end bits. Fabric consumption is the quantity of fabric which is required to produce a garment. In recent years, materials continuously increases, so any increase in material utilization rate directly affects the production cost [10]. Any reduction in the amount of cloth used per garment leads to increased profit [11]. The minimization of fabric wastage is crucial to the reduction of production costs [12].And as we all know that improving the material utilization rate is one of the most important means of reducing the production costs and improving product competitiveness [13]. Any material left in the fabric store is also a waste as it will be disposed of at a much cheaper rate [14].In garment industry, profit or lose mostly depend on the total consumption of fabric in an Abstract-In present day, the apparel industries should be very versatile and should capable of processing any kinds of design as per buyer demand. Better quality in every sense of the word warrants a better price point, but the idea and real trend are to mitigate risk and maximize net profits. During order taking, we need to make fabric consumption using mathematical estimates before actual marker making consumption. Two types of mathematical methods of fabric consumption are widely used by many factories. But due to lack of knowledge, what type of formula is suitable for which type of garments, it is not clear to all. So, the objective is to find out the accurate method of consumption when sleeve type varies. For this experiment, six garments having three different sleeve types; set-in, raglan & kimono for both short & long sleeve have been used. After that, patterns & markers are created using Lectra Modaris & Diamino software having a width of 60 inches. Then consumptions have been calculated for all six garments using two mathematical & one marker planning method. After analyzing the result, it can be concluded that for set-in sleeve single or individual formula can be used before production for fabric consumption, but in case of raglan sleeve only single formula can be used, and for kimono sleeve, only individual formula should be used. As it has been well-known that, marker planning method consumption is the best method of fabric consumption because it gives the most accurate consumption. But before production, when pattern & marker is not prepared, merchandisers have to make consumption for cost calculation and order processing. So, the guideline will help the industry by saving a lot of fabric from unnecessary wastage due to misuse of a mathematical formula.

Global Journal of Researches in Engineering ( ) Volume XIx X Issue required for costing will be less. But the development of marker is a time-consuming process since costing should be submitted to the buyer within the given time frame. Again manual marker making is not possible if multiple styles are going on at a time. To supply customers with the right products in the right place at the right time and affordable prices, it is necessary to investigate the process or method of fabric consumption based on different garment design. So, the objective of this paper is to investigate the effect of different sleeve variations & fabric consumption calculation methods on fabric consumption.

2. II.

Materials & Methods , During order taking, we need to make fabric consumption using mathematical estimates before actual marker making consumption. Mathematical methods give the fabric consumption quickly, and time For this experiment, six garments having three different sleeve types; set-in, raglan & kimono for both short & long sleeve have been used having the same GSM (160). After that, patterns have been made according to the measurements and markers have been created using Lectra Modaris & Diamino software having a width of 60 inches. Then consumptions have been calculated for all six garments using two mathematical & one marker planning method.

order. Therefore, fabric consumption must be calculated properly before fabric cutting. There are three methods to calculate the fabric consumption, namely two mathematical methods & one marker planning method.

3. Result

In this project, fabric consumptions have been calculated using three methods for six T-shirts (three short & three long) having three different types of sleeve variations (set-in, raglan and kimono sleeve). After calculation the following results have been found.

4. Result Discussion

From table 2 & figure 8, it can be said that Setin sleeve T-shirt has more efficiency than Raglan sleeve T-shirt and Raglan sleeve T-shirt has higher efficiency than Kimono sleeve T-shirt. From figure 9 &table 3, it can be said that for set-in sleeve, can use single or individual formula before production for fabric consumption, but in case of raglan sleeve, should only use single formula and for kimono sleeve, should only use individual formula.

5. VI.

6. Conclusion

blogs suggest which formula should use for what type of garments. So, this experiment have been done to show the comparison of different fabric consumption method for different types of garment products. If anyone follow the guideline or recommendation and can implement it in the industry; a lot of fabrics can be saved and hence saved money.

As it has been well-known that, marker planning method consumption is the best method of fabric consumption because it gives the most accurate consumption. But before production when pattern & marker is not prepared, apparel merchandisers have to make consumption for cost calculation for order taking & processing. Single formula or individual formula (maximum dimension) method both are used in the factory. But neither any apparel books nor any textile

| POM | Measurement Name | S | M | L | XL | XXL | Unit |

| HC | Half Chest | 48 | 51 | 54 | 57 | 60 | cm |

| HBO | Half Bottom Opening | 48 | 51 | 54 | 57 | 60 | cm |

| HPSF | High Point Shoulder Front | 70 | 72 | 74 | 76 | 78 | cm |

| NW | Neck Width | 16 | 17 | 18 | 19 | 20 | cm |

| FND | Front Neck Drop | 8 | 8.5 | 9 | 9.5 | 10 | cm |

| BND | Back Neck Drop | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | cm |

| SD | Shoulder Drop | 5 | 5 | 5 | 5 | 5 | cm |

| S | Shoulder length | 15 | 16 | 17 | 18 | 19 | cm |

| AHS | Arm Hole Straight | 24 | 25 | 26 | 27 | 28 | cm |

| SL | Short Sleeve Length | 21 | 22 | 23 | 24 | 25 | cm |

| SO | Short Sleeve Opening | 18 | 19 | 20 | 21 | 22 | cm |

| SW | Short Sleeve Width | 23 | 23.75 | 24.5 | 25.25 | 26 | cm |

| SL | Long Sleeve Length | 55 | 56 | 57 | 58 | 59 | cm |

| SO | Long Sleeve Opening | 15 | 15.5 | 16 | 16.6 | 17 | cm |

| SW | Long Sleeve Width | 23 | 23.75 | 24.5 | 25.25 | 26 | cm |

| RFSF | Raglan Forward Shoulder Front | 5 | 5 | 5 | 5 | 5 | cm |

| RFSB | Raglan Forward Shoulder Back | 3 | 3 | 3 | 3 | 3 | cm |

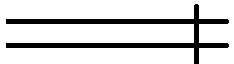

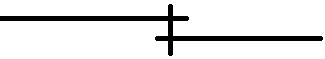

| = | ( | BL | + | SL | + | 100 ) All × | 1000 ) All × × + 100 HC × ( | 2 | × | 12 | × | GSM | + | Wastage | % | |||||||||||||

| Consumption per dozen of the T-shirt by individual formula (maximum dimension) | ||||||||||||||||||||||||||||

| Body part consumption | = | ( | BL | + | All | ) | 1000 2 ) All 100 HC 100 ( × × × × + × | 12 | × | GSM | + | Wastage | % | |||||||||||||||

| Sleeve Consumption | = | ( | SL | + | All | ) | × | 100 ( SW | 100 2 + × × | 1000 2 ) All × × | × | 12 | × | GSM | + | Wastage | % | |||||||||||

| Total consumption = Body part consumption + Sleeve Consumption | ||||||||||||||||||||||||||||

| Consumption per dozen of the T-shirt by marker planning method | ||||||||||||||||||||||||||||

| = | in the ) ( Garments ker of Inch Length Mar Number ) Inch 1000 ( Width 1550 ker Mar × × × | Marker 12 GSM × × | + | Wastage | % | |||||||||||||||||||||||

| IV. | ||||||||||||||||||||||||||||

| Sleeve Type | Efficiency found Short Sleeve T-Shirt Long Sleeve T-Shirt | |

| Set-in Sleeve | 79.40% | 83.26% |

| Raglan Sleeve | 80.86% | 79.42% |

| Kimono Sleeve | 74.51% | 50.62% |

| Fabric Consumption (Kg/Doz) | |||||||

| Formula Used | Set-in | Short Sleeve T-Shirt Raglan | Kimono | Long Sleeve T-Shirt Set-in Raglan Kimono | |||

| Sleeve | Sleeve | Sleeve | Sleeve | Sleeve | Sleeve | ||

| Single Formula | 2.436 | 2.436 | 2.436 | 3.24 | 3.24 | 3.24 | |

| Individual Formula | 2.381 | 2.736 | 2.637 | 3.113 | 3.479 | 4.709 | |

| Marker Planning Method | 2.616 | 2.452 | 2.567 | 2.943 | 3.253 | 4.921 | |