1. Introduction

retreatment of textile materials is very important, without pretreatment the coloration of cotton is nearly impossible to get the desired result. For the achievement of optimum whiteness, the removing of natural color from the grey cotton fabric is a must. S. M. F. Kabir et al shows in their study that the whiteness of cotton increases with the use of blue or optical brightening agents [1]. But there may arise some problems in case of further coloration process because blue or optical brightening agents can affect the shade of the dyed fabric. Year 2019 J Generally scouring removes all impurities except the natural coloring matters which have to be broken down by bleaching agent either with an oxidizing or reducing agent. When the color acts upon by reducing agent, there is always the possibility that the oxygen in the air may deoxidize it to its original color [2].

There are different bleaching agents for this purpose; most of them are oxidative. S. Polat et al. shows in their investigation, the amount of hydrogen peroxide has a great effect on the whiteness of cotton knitted fabric [3].

Saravanan et al. study on the bleaching effect of cotton fabrics shows that by using hydrogen peroxide, which is from glucose oxidase enzyme, shows lower whiteness values than the expectation of the commercial processes [4]. Kumbasar et al. investigation on hydrophilicity and whiteness index shows that with the increase of hydrogen peroxide and activator concentration, hydrophilicity and whiteness increase also increase [5]. With the perfect bleaching of cotton fabric, some weight loss of cotton fabric will happen. Abdul and Narendra found that in their study, with the increase in concentration of bleaching agent, whiteness index increases but the weight of material decreases [6]. In the case of weight loss, there may be an effect of bursting strength of cotton fabrics.

For the achievement of optimum whiteness index there may be loss of weight of the cotton fabric, Naser et al. try to optimize bleaching parameters for whiteness index and bursting strength of the knitted cotton fabric, they observe an inverse relation between themselves [7].

2. II.

3. Materials and Methods

4. a) Materials

100% cotton knitted single jersey (160 GSM) and hydrogen peroxide (H 2 O 2 ), sodium hypochlorite (NaOCl) and calcium hypochlorite Ca(OCl) 2 were used as bleaching agents and sodium hydroxide as a scouring agent.

5. b) Work outline

Collection g) Measurement of whiteness Index Whiteness index of the scoured and bleached sample was determined by the reflectance value of spectrophotometer (Datacolor650) at 10 0 observer and D65 illuminant.

6. h) Measurement of Bursting Strength Test

Pneumatic method (ISO 13938-2: 1999) was used for the determination of bursting strength and bursting properties of the samples [8].

7. III.

8. Result & Discussions a) Effect of hydrogen peroxide (H 2 0 2 )on whiteness

The whiteness index of the sample increases with the increase of peroxide concentration markedly upto 4.5 g/l. Further increasing of hydrogen peroxide does not play a significant role in increasing whiteness index, and 4.5 g/l is the optimum concentration. From figure 6, it is clear that for increasing concentration of sodium hypochlorite, whiteness index increases.

9. d) Effect of Sodium Hypochlorite (NaOCl ) on bursting strength

Figure 7 shows that the bursting strength of the samples are almost same.

10. f) Effect of Calcium Hypochlorite Ca(OCl) 2 on bursting strength

The graph shows that for the higher concentration of calcium hypochlorite, bursting strength was less. At a concentration of 3.5g/l to 5.5g/l of Calcium Hypochlorite Ca(OCl) 2 bursting strength are same.

11. Conclusion

With the increase of the concentration of Hydrogen peroxide (H 2 O 2 ), Sodium Hypochlorite (NaOCl), and Calcium Hypochlorite Ca(OCl) 2 , there is a significant improvement in the whiteness index of the bleached cotton fabric. When the concentration of Hydrogen peroxide (H 2 O 2 ), Sodium Hypochlorite (NaOCl) Calcium Hypochlorite Ca(OCl) 2 was over 3.5 g/l, there was no remarkable change in whiteness. However, 4g/l concentration for Hydrogen peroxide (H 2 O 2 ), and 3.5 g/l for Sodium Hypochlorite (NaOCl), and Calcium Hypochlorite Ca(OCl) 2 , are the optimum concentration for suitable bleaching because though further increase in concentration, increases whiteness index but bursting strength of the cotton fabrics decreases due to hydrolyzation of cellulose.

| of Grey Fabric |

| â??" |

| Scouring and bleaching |

| â??" |

| Whiteness Test (By Using Spectrophotometer) |

| â??" |

| Bursting strength Test (By Using Bursting Strength |

| Tester) |

| â??" |

| Result and Discussion |

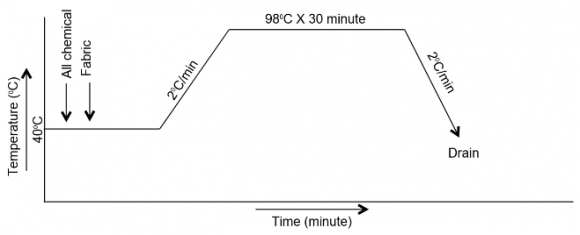

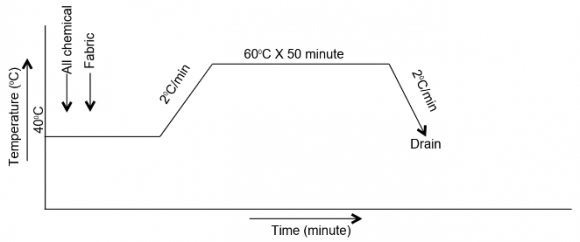

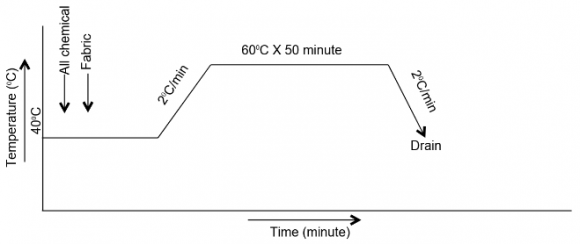

| c) Scouring & Bleaching Recipe |

| Different bleaching agents at different |

| concentration were used in this research paper for |

| investigation of whiteness index and bursting strength of |

| 100% cotton knitted single jersey. |