1. Introduction

he art of applying color in fabrics has been known for a long time. Historical records of the use of natural dyesextracted from vegetables, fruits, flowers, insects and also fish date back to3500 BC. However, the importance of natural dyes disappeared since the advent of synthetic dyes, which have a wide range of colors and shades as their main advantages (Gurley, 1996;Kant, 2012).

The generation of liquid effluents isa significant environmental problem, since mostsynthetic dyesare complex aromatic molecular structures, which make them inert with difficulty inbiode grading when discharged into the environment(Khouni, Marrot, Moulin, & Ben Amar, 2011; Samanta & Agarwal, 2009).

In the last years, the dyestuffs in dustry has been increasingly forced to reducetoxic effluents and stop the production of potentially azardous dyes and pigments (Mirjalili, Nazarpoor, & Karimi, 2011).Moreover, due to the in creased perception of environmental and health risks associated with the synthesis, processing, and use of synthetic dyes, interest in natural dyes has in creased worldwide. Therefore, a new market that value sproducts originated from natural raw materials is growing, with huge advantages to the environment (Ali, 2007;Becht old & Mussak, 2009). Natural dyes are environmentally compatible, biodegradable, nontoxic, free of allergic effects, as well as available from a wide range of sources that includes coloring from plants, insects, fungi and minerals(Ibrahim, El-Gamal, Gouda, & Mahrous, 2010).

Among such a wide range of natural dyes, eucalyptus deserves special attention because this tree may be found in many countries. The main components of eucalyptus leaves that are responsible for the color given to textile materials are tannins (gallic acid and ellagic acid) and flavonoids (rutin and quercetin). These substances are considered very use fulduring the dyeing processdue to their ability to fix the dye within fabrics. Figure 1 shows the structures of the components responsible for color found in eucalyptus leaves . In all molecules there are hydroxyl groups and oxygen atoms that may be related to hydrolysis or partial charges, which are probably responsible for attraction to the silk residual groups. The silk is composed of a protein called fibroin surrounded by a gum called silk sericin, removed in the degumming process. Therefore, the silk fabric is basically fibroin. Fibroin consists of a long parallel chain containing about 400 amino acid residues with the structure of the general type as shown in Figure 2 (Iqbal, 2008). In the dyeing process, the colorants in solutions hould adsorb, diffuse in to the fiber and finally, establish with it physicochemical linter actions (Alcântara & Dalt in, 1996;Salem, 2010). Unfortunately, such mechanisms are not well understood as the process is stillempirical. The dyeing procedure and mainly the adsorption mechanism have been scarcely reported.

In this context, the objective of this work was to study the ideal conditions for silk dyeing with eucalyptus leaves extract. Parameters such as initial concentration, pH and temperature were investigated. The amount of eucalyptus extract retained and color fastness to washing were the response parameters. The dyeing mechanism was investigated through kinetic and isotherm models. Thermodynamic parameters were also obtained.

2. II.

3. Material and Methods

4. a) Materials

Eucalyptus leaves (Eucalyptusgrandis) were used in this work. Initially, the fresh eucalyptus leaves were dried in the open air for fifteen days and crumbled in a blender.

Solutions of the eucalyptus leaves extract were prepared adding 10, 15 or 20 g of crumbled leaves in 1000 mL of distilled water. Samples were then heated with stirring at90 °C for 60 min and then filtered. The filtrated solution was used in the dyeing process.

Pure silk fabric ready for dyeing (70 gm-2 ) was used. The non-ionic detergent Nionlab CELM was applied in the fastness to washing procedure. Concentration of 2 g L-1 was used.

5. b) Dyeing process

Influence of temperature, pH and initial concentration of extract solutions was studied through a2 3 complete factorial design composed of eleventrials, three trialsas the central point. Dyeing of each sample lasted 60 minin AT1-SW Kimak equipment with a liquor ratio 1:100.The response variable was the amount of extract adsorbed in the fabrics. Table 1 lists the variables and levels for dyeing. Design-Expert software version 7 was used.

Table 1: Factorial design for dyeing of silk fabrics After dyeing, the samples were subjected to washing with the non-ionic detergent solution at 60 °C for 10 min., rinsed in cold water and dried at room temperature.

The amount of extract adsorbedper gram of silk (q) (mgg-1 ) was determined through a mass balance as described in Equation( 1): (1) where Vis the volume of the solution(L), W is the weight of the silk (g), C0 is the initial concentration of extract(mgL-1 )and Cfis the extract concentration after dyeing(mgL-1 ). Concentration of the dyeing solutions was analyzed through spectro photometry. At first, the wavelength of maximum absorption (? max ) of the filtrated solution was obtained through the 1601DCS himadzue quipment. Biospectro SP 22 spectrophoto meter was calibrated with ? max to obtain the extract concentration in solution.

( )

W V C C q f ? = 0 c) Kinetic of6. the dyeing process

Silk fabrics were put in contact with eucalyptus extract in AT1-SW Kimak equipment in the experimentally optimized conditions given by the response variable of Table1.

The fabrics were fast removed after dyeing at different times. After cooling, all effluents were subjected to spectro photometric reading and extract concentrations determined.

The amount of extract adsorbed per gram of fabric (qt) (mg g-1 ), at any time t, was calculated using Equation (1), where Cf takes the value of the concentration at time t (Ct).

Experimental data was modeled through the pseudo-first order and pseudo-second order kinetic models. The pseudo-first order kinetic equation is the well-known Lagergren Equation (Lagergren, 1898). It may be expressed as: (2) where q e (mg g-1 ) stands for the amount of eucalyptus extract when equilibrium is reached and k1 is the pseudo-first order rate constant (min-1 ).

For the integration of Equation ( 2) with boundary conditions at t = 0, qt = 0, and at t = t, qt = qt, the nonlinear form of the equation becomes:

(3)

The pseudo-second order equation is:

(4)where k 2 is the pseudo-second order rate constant (g mg-1 min-1 ) (Ho, 2006).

7. Integration of Equation (4) generate:

(5)

The pseudo-second order rate expression is used to describe chemisorption involving valence forces through the sharing or exchange of electrons between the eucalyptus extract and the fabric as covalent forces (Ho, 2006).

8. d) Equilibrium of the dyeing process

The equilibrium data was carried out using solutions of extract with different concentrations at 70, 80 and 90 ºC and the best pH given by results of the factorial design. Solutions were put in contact with the silk samples up to the equilibrium time obtained in the previous section.

The Langmuir adsorption isotherm has been successfully applied to a wide range of aqueous adsorption processes, including dyeing(Arora, Gupta, Rastogi, & Gulrajani, 2012; Kong kachuichay, Shitangkoon, & Hirunkitmonkon, 2010; Lagergren, 1898). A basic assumption of the Langmuir theory is that adsorption takes place at specific homogeneous sites within the adsorbent. It is then assumed that once a dye molecule occupies a site, no further adsorption can take place at that site. Theoretically, a saturation value is reached when no further adsorption can take place. The saturated monolayer curve can be represented by the Equation ( 6): (6) where in the equation, qmax (mg g-1) is the maximum amount of the eucalyptus extract per unit weight of silk to form complete monolayer coverage of the surface. It represents a practical limiting adsorption capacity when the surface is fully covered with dye molecules; b is the Langmuir constant related to the affinity of binding sites (L mg-1) (Arora et al., 2012;Lagergren, 1898;Langmuir, 1918).

The Freundlich model assumes a heterogeneous adsorption surface with sites that have different energies of adsorption and are not equally available. Besides being more applicable, the Freundlich isotherm provides no information on the monolayer adsorption capacity. It predicts a multilayer adsorption process and is written by Equation ( 7): (7) where kF is the adsorption equilibrium constant of Freundlich (L g-1) and n is the heterogeneity. In general, as the kF value increases, the adsorption capacity increases. Values of n between 1 and 10 show favorable adsorption. If n < 1 and n?0, the silk fabric is saturated with the eucalyptus extract since adsorption energies decreases with surface density (Dávila-Jiménez, Elizalde-González, & Peláez-Cid, 2005; Freundlich, 1906).

The experimental data may be also fitted to the three-parameter model of Langmuir-Freundlich when the two-parameter models of Langmuir and Freundlich do not provide reasonable results. The Langmuir-Freundlich model is able to describe both the adsorptive behavior characteristic of the Langmuir type as the Freundlich. Normally this model fits better in cases where the adsorbent has heterogeneous surface, as it is the case of silk, (Iqbal, 2008;Needles, 1986) and is commonly expressed by the Equation ( 8): (8) Where KLF is the adsorption constant of Langmuir-Freundlich (L mg-1), qmaxis the maximum )

t e t q q k dt dq ? = 1 ) 1 1 ( 1 t k e t e q q ? = ( ) 2 2 t e t q q k dt dq ? = t k q t q k q e e t 2 2 2 1+ = e e e bC bC q q + = 1 max n e F e C k q = ] ) ( 1 [ ] ) ( [ n e LF n e LF m e C K C K q q + =adsorption capacity (mg g-1), and n is the parameter of heterogeneity (Chiou & Li, 2003).

9. e) Thermodynamic parameters

Gibbs free energy (Î?"Gº), enthalpy (Î?"Hº) and entropy (Î?"Sº) were calculated by the Equations ( 9), (10) and (11) in 70, 80 and 90 ºC.

(9) (10) (11) where K c is the equilibrium constant, and C ad , e and Ce are the eucalyptus extract concentration adsorbed at equilibrium with the concentration in the fluid phase (mg L-1 ), respectively.

10. f) Color fastness to washing

Sample dyed in the experimental optimized conditions provided by results of Table 1 was submitted to color fastness to washing.

The wash fastness test followed the procedures of ISO 105-C06: 2006 A1S cycle -Tests for color fastness: Part C-06: Color fastness to domestic and commercial laundering (ISO, 2006).Evaluation of the transfer and change of color of the samples was performed using 550 Data color spectrophotometer.

11. III.

12. Results and Discussion

13. a) Wavelength of Maximum Absorption

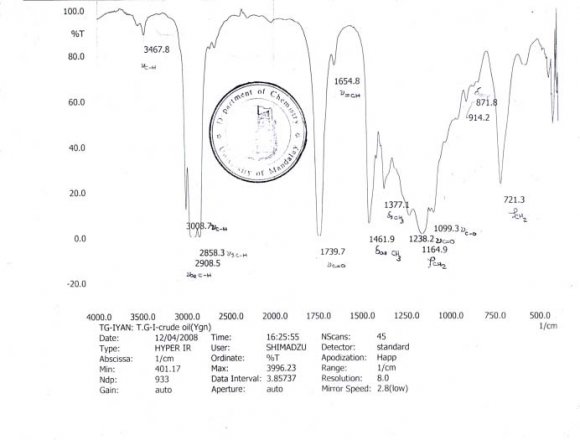

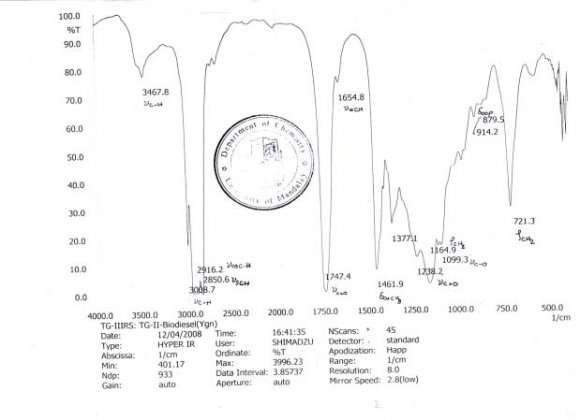

The UV-Vis wavelength range is show in Figure 3 The wavelength of 380 nm was used in all concentration analysis due to experimental limitations of the Biospectro SP22 UV-Visible spectrophotometer, with a range of 300-1000 nm.

14. b) Silk Dyeing with Eucalyptus Extract

All samples of the dyeing process showed different yellowish-brown coloration, according to the amount of extract adsorbed. Results of the factorial design are shown in Table 2. Table 2: Results of the 2 3 factorial design used in evaluating the influence of the variables on the response (q) for the silk dyeing with eucalyptus extract It was seen that the initial concentration of extract had a huge influence in the amount of eucalyptus extract retained in the silk fabric. Actually, concentration of 20 g L-1 promoted higher values of q than the diluted concentration of 10 g L- 1 . It happened due to the increase of the concentration gradient. Then, it may be concluded that initial concentration of extract played an important role in the adsorption capacity of eucalyptus extract onto silk, which is in total agreement with results already reported ( Increasing temperatures also favored the adsorption process. It may be seen that 90 oC originated higher values of q if compared to 80 oC. It emphasizes that chemisorption is very important in the dyeing process. The positive influence of temperature may reflect an increase in the mobility of large extract molecules. If so, an increase in the number of molecules interacting with the active sites at the silk fabric was expected (Lagergren, 1898).

15. Global

Lower pH values provided higher q values. As the isoeletric point of silk filber varies between pH 3.6 and 5.2(Sashina, Bochek, Novoselov, & Kirichenko, 2006) at pH 3 the fiber was more positively charged. In this case, the acidic and, especially the protonated amino groups of the silk fiber are of prime importance in the uptake of anionic dyestuffs presented in the eucalyptus extract (Lagergren, 1898). In such a case, adsorption occurred as a result of electrostatic forces, such as ion-ion forces and H-bonding, with van der Waals forces and hydrophobic interaction. Although not knowing all molecular structures presented in the eucalyptus extract, probably ? -? could not be neglected as well (Tang, Tang, & Yang, 2010).

Specifically, the attraction between the eucalyptus extract and the fiber may have occurred primarily by the large amount of tannins in the eucalyptus leaves, since tannins contain phenolic compounds that can form hydrogen bonds with the carboxyl groups of silk. There are two other possibilities of interaction involved: (a) anionically charged phenolic groups form an ionic bond with cationic (amino groups) in the silk, and (b) a covalent bond may also form through an interaction between any quinine or semiquinone groups present in the tannins and suitable reactive groups on the silk . Such mechanism may emphasize the main contribution of chemisorption although physisorption could be also present (Tang et al., 2010).

Considering the dyeing parameters studied herein, the highest response value was found in test 4, in which the initial concentration of 20 g L-1 , pH 3 and 90 ºC promoted the highest amount of 350 mg of eucalyptus extract per g of silk. The effect and the contribution percentage on the response variable (q) are shown in Table 3. Table 3: Main effect and interaction between variables and the percentage contribution of the effects on the response variable for silk dyeing with eucalyptus extract It was seen that the initial concentration of eucalyptus extract had the greatest contribution in increasing the response variable (q), followed by pH and the temperature. Furthermore, the effect of pH on response variable was negative. It means that an increase in that variable decreased the value of q, which is in agreement with the experimental data.

16. Global

17. c) Adsorption Kinetics

Figure 3a shows that the kinetic data carried out under the optimal conditions of 20 mg L-1, 90 oC and pH 3 given by test 4. It may be seen that adsorption was very fast in the early stages of contact and gradually decreased with time until it remained constant in the optimum contact time of 60 min. The same behavior was observed in the work of Septhum et al. (2009) and Samanta & Konar (2011). Hence, subsequent equilibrium experiments took into account such contact time. The higher dyeing rate in the early stages is possibly due to a large number of available sites of adsorption in the silk. Decrease in the adsorption rate was a consequence of decrease in the concentration gradient due to the increased number of sites already occupied by the extract molecules.

The nonlinear fit of pseudo-first-order and pseudo-second-order models is shown in Figure 3b and c, respectively. It was observed experimental data was better described by the pseudo-second order model. Indeed, Table 4 presents the quantitative results of the adjustments. It can be seen that higher correlation factor R 2 occurred in the pseudo-second-order model. Moreover, the amount of eucalyptus extract experimentally retained in the equilibrium was very similar to the value estimated through the model.

18. Table 4: Comparison of kinetic models pseudo-first and second-order

These data suggested that pseudo-second order kinetics model was predominant and that the overall rate of adsorption of eucalyptus extract on silk was likely controlled by the chemisorption process (Lagergren, 1898). Adsorption of dyes in specific sites of silk was already reported(De Giorgi & Cerniani, 1991) and this is in agreement with the influence of temperature and the possible attraction of the molecules to the positively charged silk at pH 3.

19. d) Adsorption Isotherm

Equilibrium data and adjustments to Langmuir, Freundlich and Langmuir-Freundlich isotherm models are shown in Figure 4a, b and c, respectively. At first, it should be emphasized the favorable shape of the isotherms, mainly with increasing temperatures, which is characteristic of endothermic processes. This result may reflect an increase in the mobility of the dye ionic charges with temperature as already discussed. In the very beginning of the isotherm it was seen an induction period, which means that the dye molecules had nearly the same affinity for more dye molecules as the initial sites of the silk fabric, characteristic of cooperative adsorption. The rise and the pronounced plateau was attributed to the development of the monolayer as a new surface where chemisorption could also occur. Then, this plateau represented the saturation of such new surface. These isotherms may be classified as type S2 according to Giles, MacEwan, Nakhwa, & Smith(1960). Pseudo first-order model 372 k 1 (min -1 ) q e,cal (mg g -1 ) R 2 0.10091 ± 0.015 355 ± 12 0.946 Pseudo second-order model k 2 (g mg -1 min -1 ) q e,cal (mg g -1 ) R 2 0.00034 ± 0.000r06 399 ± 12 0.978

It is well known that the Langmuir model may represent equilibrium data where chemisorption process is involved, forming a dye monolayer in the silk (Chairat Possibly, the monolayer occurred with the interaction between the hydroxyl groups of the dye and the amino groups of the silk protein, (Vinod et al., 2011) as already seen. On the other hand, the Freundlich model is related to a multilayer process and may represent some dyeing process as well (Chairat et al., 2005;Sawada & Ueda, 2003). Therefore, the Langmuir-Freundlich model that emphasizes the importance of both phenomena comes naturally as the model that may represent the equilibrium data of the eucalyptus extract in the silk fabric. In fact, experimental data obtained at 70, 80 and 90 ºC were visually better adjusted to such model.

Regression parameters for the model of Langmuir, Freundlich and Langmuir-Freundlich are shown in Table 5. Actually, neither Langmuir nor Freundlich single models provided reasonable adjustments according to the low correlation factor R 2 and high deviations of the parameters. As already expected, equilibrium data was better fitted to the Langmuir-Freundlich model, which is in total agreement with the isotherm shape.

20. e) Thermodynamic parameters

The results of the thermodynamic parameters, Î?"G°, Î?"H° and Î?"S° of eucalyptus extract adsorption are shown in Table 6. The highest value of K was obtained at 90 °C, indicating the most favorable equilibrium among the temperatures studied herein. Such results were in agreement with isotherm experimental data and the factorial design. Î?"G°values were all negative, indicating that the process was spontaneous. Moreover, the increase in the temperature provided a slightly decrease in the free energy. Such phenomenon may indicate that: firstly, it is possibly related to the contribution of the c chemisorption in the process of retaining the eucalyptus extract in the fiber (Komboonchoo & Bechtold, 2010) and secondly, as the numerical values were very close to each other, it confirmed the small and positive contribution of temperature (5.10%) in the dyeing process. In confirmed that the dyeing process was endothermic (Î?"H°>0) as also previously observed (Vinod et al., 2011).

The positive value of Î?"S° suggests an increase of randomness at the solid-solution interface, originated of some structural changes in both adsorbent and adsorbate. These high values Î?"S° are typical of endothermic processes (Hill Jr., 1977).

21. f) Color Fastness to Washing

The indices of wash fastness in the optimized conditions (initial concentration of extract of 20 g L-1, pH 3.0 at 90 °C) were considerable as acceptable. The color change was 3-4, while the staining on cotton and wool presented note 4.

The good fastness properties of dyed silk fabric can be a consequence of the covalent bonds of tannins with the fiber, as seen previously .

IV.

22. Conclusion

From this study it can be concluded that the silk fabrics can be easily dyed with eucalyptus extract yielding a yellowish-brown color. The best result was achieved using a dyeing temperature of 90 °C at pH 3 and 20 gL-1 as extract initial concentration.

By the way, concentration of the initial solution was the most relevant parameter of dyeing, followed by pH and temperature.

The pseudo-second order model best represented the kinetic data whereas equilibrium data was adequately modeled with Langmuir-Freundlich equation. This adjustment may indicate that chemisorption has a huge importance in the dyeing mechanism. Probably the first monolayer based on ionic bonds acted as another adsorption sites for a multilayer formed by hydrogen and covalent bonds.

The thermodynamic parameters Î?"H°, Î?"G° and Î?"S° showed that the silk dyeing is an endothermic and spontaneous process with increased randomness at the solid-solution interface.

The good fastness to washing probably occurred due to the presence of tannins in the eucalyptus extract that acted as mordant.

| Year 2018 |

| 2 |

| XVIII Issue I Version I |

| Global Journal of Researches in Engineering ( ) Volume C |

| © 2018 Global Journals |

| The Langmuir-Freundlich model may predict | includes | contribution | of | physisorption | and |

| qmax close to the experimental value qmax.exp at 70, | chemisorption, with n equal to unity. | ||||

| 80 and 90 ºC. The heterogeneity parameter, n, assumes | |||||

| values slightly greater than unity, indicating an | |||||

| approximation to Langmuir isotherm, with the formation | |||||

| of a homogeneous monolayer. Similar results can be | |||||

| seen in Tang et al.(2010) where adjustments to | |||||

| Langmuir-Freundlich model were obtained. Such model | |||||

| Natural Dyeing of Silk with Eucalyptus Leaves Extract | ||||||

| Year 2018 | Isotherm | Parameters q max exp. (mgg -1 ) | 70 ºC 376 | 80 ºC 402 | 90 ºC 428 | |

| 8 | Langmuir | q max (mg g -1 ) B | 640 ± 77 0.00008 ± 0.00002 | 721 ± 102 0.00008 ± 0.00002 0.00012 ± 0.00003 661 ± 68 | ||

| XVIII Issue I Version I | Freundlich Langmuir-Freundlich | R 2 k F N R 2 q max. (mgg -1 ) k LF N R 2 | 0.974 0.81 ± 0.65 1.58 ± 0.22 0.929 414 ± 11 0.00019 ± 8.22.10 -6 0.00019 ± 9.17.10 -0.971 0.68 ± 0.57 1.52 ± 0.21 0.928 440 ± 14 6 1.87 ± 0.12 1.96 ± 0.15 0.998 0.997 | 0.972 1.68 ± 1.31 1.74 ± 0.26 0.913 458 ± 8.7 0.00024 ± 7.48.10 -6 1.96 ± 0.11 0.998 | ||

| ( ) Volume C Global Journal of Researches in Engineering | Temperature (°C) 70 90 80 | K c 45.76 55.76 49.78 | Î?"G°(J mol -1 ) -10934 -12166 -11283 | Î?"H°(J mol -1 ) 10258 | Î?"S°(J mol -1 K -1 ) 61.61 | |

| © 2018 Global Journals | ||||||