1. Introduction

rinding is one of the metal removal processes used in finishing of components that require close dimensional tolerances and smooth surfaces. Cutting fluid is commonly used to flood the grinding zone, to meet both cooling and lubrication requirements. The ingredient of conventional cutting fluids causes skin and respiratory problems to machine operators. The high cost of disposal or recycling of the grinding fluids is another major concern, especially in the environmental pollution point of view. Use of vegetable oils along with nanomaterials makes possible the developments in the new generation of cutting fluids to achieve high performance in machining, combined with good environmental compatibility. The traditional methods of applying cutting fluid are not ecological, and hence the Minimal Quantity Lubrication (MQL) has been gaining as an alternative solution for flood cooling. [1][2][3][4].

Alves et al. [5] developed water-based grinding fluids consists of sulfonate vegetable oil in water to meet CBN grinding needs and is of environmentally friendly. The quality of oil was evaluated by conducting various tests and proved that the proposed oil is readily biodegradable. The performance of new oil was evaluated and expressed regarding of G-ratio (volume of metal removed per unit volume of wheel wear). The results compared with semi-synthetic oil and mineral oil. The semi-synthetic oil acts as a good coolant but not a good lubricant and hence less G-ratio. The mineral oil acts as both lubricant and coolant hence high G-ratio. The proposed oils have G-ratio almost same that of mineral oil. Bin shen et al. [6] Performed experiments on surface grinding with the applications of water-based Al2O3 and diamond nanofluids by MQL. The experiments results were compared with dry machining and reveal that the volume of metal removed per unit volume of wheel wear has improved with the application of highly concentrated nanofluids in addition to the reduction of cutting forces, improvement in surface finish and minimized the workpiece burning. Ramana et al. [7] prepared a green and petroleum-free cutting fluid by mixing canola oil with nano-crystalline boric acid. They conducted experiments on turning of AISI 1040 to study the effect of nano-level boric acid particle size and its percentage of weight in lubricant on surface roughness, cutting forces and cutting zone temperature. The surface roughness, cutting forces and cutting zone temperature are found to be directly proportional to the percentage of weight and inversely proportional to the nanoparticle size.

2. Experimental Investigation of Surface

Roughness and Temperature on a Surface Grinding of HC-HCr Steel using Dry and MQL Techniques Nihat Tosun and Hasim Pihtili [8] experimented MQL in the face milling process with different machining parameters such as spindle speed, feed on 7075 Al alloy. The optimum cutting parameters were determined by Gray relation analysis for improving surface finish and metal removal rate. Lee et al. [9] conducted experiments with compressed air as cutting fluid in micro-grinding to reduce the cutting forces and improving the surface finish while maximizing the metal removal rate. The response surface models were prepared by using experimental results, for grinding forces and surface finish in terms of depth of cut, feed rate and air temperature Using Multi-objective optimization technique, the optimal values of depth of cut, feed rate, and air temperature are obtained for minimum Specific grinding force, surface roughness and maximum specific MRR and then the models are validated.

Vasu and Pradeep Kumar Reddy [10] investigated the effect on surface roughness, tool wear, and temperature dissipation of suspending Al2O3 nanoparticles in Coolube 2210EP eco-friendly vegetable MQL oil when machining Inconel 600 alloy at different cutting parameter combinations by coated carbide cutting tools on a precision engine lathe machine. Experimental results show that surface roughness, temperature, cutting force, and tool wear are reduced significantly by MQL with (6 vol. % of the Al2O3 particle) nanofluids than dry. Neseli et al. [11] Conducted experiments on CNC grinding Machine to determine the process parameters for improving surface finish and reducing the wheel vibrations for AISI 8620 sheets of steel. With experiments and Taguchi method the optimal process parameters were determined. Using Response surface analysis, two optimized models were developed to predict the most significant grinding parameters for minimum surface finish and vibrations. The results are further validated.

Hadad and Hadi [12] investigated the grinding of S34700 steels and AA6061 Al alloy on NC-Grinding machine by using vegetable & synthetic ester oil in MQL system. The performance of oils was evaluated for surface quality, cutting forces and surface temperatures. The result shows that the good grinding performance was found with synthetic ester oil than vegetable oil in MQL system. But in case of AA6061 Al alloy, the use of vegetable oil MQL system was found to produce a smooth surface. Nageswara Rao and Vamsi Krishna [13,14] conducted experiments on turning EN8 steel using carbide cutting tools using Boric acid as solid lubricant have reported considerable improvement in the machining performance by reducing cutting forces and tool wear, and improved surface finish in comparison with dry and wet machining. Vafaeesefat [15] performed tests on creep feed grinding of Rene 80 nickel-based superalloy. An ANN-based model used for optimal machining parameters to predict the grinding forces for maximizing MRR. Shen et al. [16] performed experiments in MQL grinding on cast iron by waterbased Al2O3 and diamond nanofluids. The performance of grinding was evaluated by wheel wear and tribological characteristics in dry, pure water, and MQL grinding processes. The results show an improvement in surface finish with reduction of grinding forces and grinding zone temperature.

Rodrigo Panosso et al. [17] studied the of Drilling alpha-beta Ti6Al4V alloy plates using class K10 carbide drills with and without hard coating (TiAlN, CrCN or TiCN) in MQL. The performance of the drilling was evaluated by considering the temperature rise with external MQL by the nozzle and also internal MQL of the drill. From the experimental results, it has been concluded that temperatures observed in MQL applied with an external nozzle is 50% greater than that of MQL internally through the cutting tool. The effect of coatings on drills has no influences on temperature variation in MQL applied with an external nozzle. It also observed that the feed forces were reduced with a rise in temperature. A case study was conducted by Domnita Fratila and Cristian Caizar [18] on face milling of AlMg3 in MQL using LUBRIMAX oil and flood lubrication using SAROL 474 EP emulsion with face milling cutter. The Taguchi technique was employed for determining optimal process parameters and lubricant flow rate to minimize surface roughness and power consumption. From the results, they concluded that with the combination of high cutting speed and low values of depth of cut, feed rate, lubricant flow rate produce a good surface finish. Similar results were observed when using MQL and flood lubrication.

From the literature, it has been found that the surface finish is influenced by machining parameters like wheel speed, depth of cut and table feed rate. In addition to that, cutting fluids and its method of application will also affect the surface finish, the surface temperature of workpiece and cutting force needed for machining.

3. a) Response Surface Methodology

Nowadays, the RSM has become a popular optimization tool used for multi-response optimization of process parameters in different applications. RSM is a statistical technique to develop mathematical models or relations between responses and controllable process parameters. These models are also called as prediction models used to predict process variables for required responses. In RSM, the quantitative relationship between input and output variables is presented as follows [19]:

Y= f (x 1 ,x 2 ,x 3 ,?., x n ) +-er(1)'y' is desired response and 'f' is the response function, dependent variable and x 1 , x 2 , x 3 , ?..,x n independent variables and 'er' is the fitting error.

In the present work, sixteen experiments have been planned according to central composite design. The RSM technique is used to analyze the experimental data to identify significant parameters that affect the surface roughness and temperature. In addition to that, three-dimensional plots are constructed to study the two-factor interaction on the responses using Design Expert 8.3 software. The same RSM is used for multiresponse optimization of process parameters for dry and MQL grading.

4. ) Materials and Cutting Fluids

The experimental investigation is performed on HC-HCr steel having specifications of 150X25X25mm. The chemical composition of HC-HCr steel is presented in Table 1. The workpiece used in this work has 0.4% of carbon content with greater strength and 95.25HRB of hardness. In the present work, four cutting fluids are prepared by mixing of castor vegetable oil with different proportions (0%, 1%, 2% and 4% by volume) of Al2O3 nanoparticles to investigate its effect on surface roughness and temperature. The castor vegetable oil is abundantly available in the India and has a thermal conductivity of 0.179 to 0.188 w/mok and kinematic viscosity of 78.2 mm2/sec. The mixture of oil and nanoparticles are stirred well of about 1hour before using it for experimentation. The percentage of nanoparticles is restricted to 4% because it is increasing the density of cutting fluid [6].

5. c) Experimentation

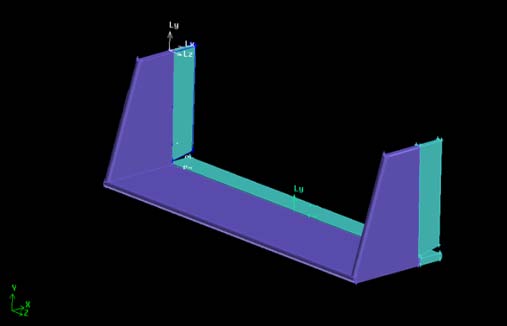

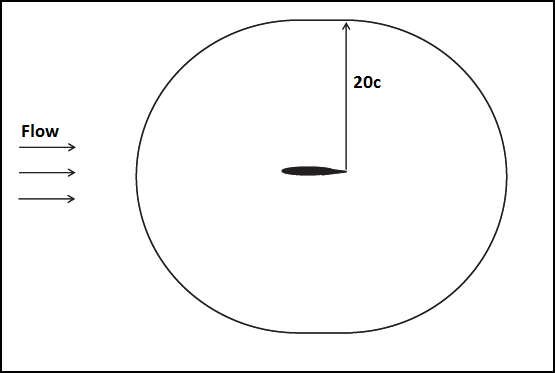

The experimental work is conducted on GREAT precision Oil dip surface grinding machine. The experimental setup is shown in Figure 1. Two experimental plans are prepared for dry and MQL grindings separately with four levels of cutting speed, depth of cut, table feed and % by weight of nanoparticles in the cutting fluid as shown in Table 2. According to Taguchi orthogonal array of L16, sixteen experiments are planned for the two cases as shown in the Tables 5 and 6. Each experiment is started with the new working condition, and experimental data of surface roughness and temperature are collected and presented in the Tables 2 and 3. In the first stage, the grinding experiments are conducted in dry condition and in second stage, experiments are conducted with vegetable oil as cutting fluids along with different mixing ratios of the nanoparticle. The workpiece is provided with a hole at its bottom, and a thermocouple is inserted in the workpiece to measure the temperature rise while machining. A digital temperature indicator is connected to the thermocouple to display temperature. An MQL fluid delivery system is designed, fabricated and provided to the machine for the supply of cutting fluid. The delivery system consists of a mixing chamber that is connected to nanofluid tank and air compressor. Nanofluid entered into the mixing chamber and delivered to grinding zone with the help of compressed air through a nozzle. Year 2017

6. Global Journal of Researches in Engineering ( ) Volume XVII Issue VII Version I A

The flow of oil and air into the chamber is regulated with a control valve provided to the delivery system. In the present work, the flow of air and oil is kept at constant pressure for all experimental runs. After each experiment, the surface roughness of the machined surface is measured with METACO METRIX MICROSURF-10, a portable surface tester at three different locations and an average Ra value is taken.

7. II.

8. Results and Discussions

Experimental results of surface roughness, grinding temperature for sixteen experiments in dry and wet grinding are presented in the Tables 4 and 5 respectively.

9. Design of experiments and experimental results for dry grinding

Exp.

No.

10. Design of

11. a) Analysis of surface roughness under dry grinding

The experimental data of surface roughness is analyzed with ANOVA and it is carried out at 95% confidence level to identify significant process parameters on the response. The p-value of process parameters indicates their significance on the surface roughness. The process parameters in the ANOVA table, which are having a p-value less than 0.05, are indicated as significant parameters [20]. Table 6 shows the dry machining data that has been analyzed with ANOVA for surface roughness, at 95% confidence to identify significant process parameters. As shown in Table 5, the model term is having a p-value of 0.0004 that indicates that the ANOVA of surface roughness is acceptable. The p-value of the depth of cut is 0.0001. Therefore the depth of cut is a significant parameter which affects the surface finish.

12. b) Analysis of grinding temperature under dry grinding

Table 7 shows the dry machining data that has been analyzed with ANOVA for grinding temperature at 95% confidence to identify significant process parameters.

The model term having a p-value of 0.0001, hence the ANOVA of surface roughness is acceptable. The p-values of cutting speed, table feed and depth of cut are less than 0.05 and reflect that all the selected parameters will affect the grinding temperature significantly. In dry grinding, there is no lubrication or cooling medium at the interface of grinding wheel and workpiece. Hence, an increase of cutting parameters results load on the grinding wheel and generates friction and temperatures at grinding zone. Since there is no chip flushing by cutting fluid, some of the chips accumulated near the grinding zone and result increased surface roughness by rubbing.

13. c) Analysis of surface roughness with MQL

Similarly, ANOVA is further extended to the analysis of surface roughness which has been obtained with MQL. As shown in Table 8, the model term is having a p-value of 0.0305 that indicates that the ANOVA of surface roughness is acceptable. Percentage of nanoparticles in MQL and table feed is having a pvalue of 0.0187 and 0.0368 respectively, indicates that these factors will affect the surface finish predominantly when it is machined with MQL grinding process.

Similarly, ANOVA is further extended to the analysis of surface roughness which has been obtained with MQL. As shown in Table 9, the model term is having a p-value of 0.0305 that indicates that the ANOVA of surface roughness is acceptable. Percentage of nanoparticles in MQL and table feed is having a pvalue of 0.0187 and 0.0368 respectively, indicates that these factors will affect the surface finish predominantly when it is machined with MQL grinding process.

14. d) Effect of process parameters on surface roughness

Figures 2(a to f) are the three-dimensional surface plots for the surface roughness of the ground workpiece. The figures show the two-factor interaction of percentage of nanoparticle in MQL cutting speed, table feed and depth of cut on surface roughness. Figures 2 (a to c) show that the surface roughness is found to be minimum at 4% of nanoparticles in MQL, cutting speed of 22.92m/s, depth of cut of 10 µm and 12 m/min of feed rate. In figure 2(d to f), the surface roughness is found to be minimum at 4m/min of table feed, 22.92 m/sec of cutting speed. The depth of cut has a moderate effect on the surface roughness. When the cutting oil is applied as MQL, the lubrication minimizes the friction and cutting forces during machining. In addition to this, the air flushes the chips and minimizes the rubbing of chips on ground surface. While cutting fluids are used along with nanoparticles, a few of nanoparticles deposited on the wheel surface and perform additional fine machining and results in enhancement of surface finish [6].

15. e) Optimization Results

In the present work, multi-response optimization is carried out for optimization of process parameters using MINITAB 17 software. The figure 4 shows the response surface optimizer plotted from the experimental results. Response optimizer is a tool to identify the optimal controlling variables to achieve required responses with a concept of Desirability. The optimization carried out for minimization of surface roughness and temperature. The desirability of surface roughness and temperature and composite desirability are found to be 1. That indicates that the optimization is valid for minimum values of responses. The optimal values of % of Nanoparticles, cutting speed, table feed and depth of cut are found to be 0.3636%, 9.166m/s, 7.12m/min and 10µm respectively.

16. III.

17. Conclusion

In the present work, experimental investigation of surface roughness and the temperature is conducted on surface grinding of AISI 1030 in dry and MQL along with nanoparticles. According to CCD of RSM technique, sixteen experiments are conducted in both the cases and experimental results of surface roughness and temperature are analyzed. The following conclusions can be drawn from this work:

In the dry grinding process, the depth of cut is found to be significant in ANOVA of surface roughness. Whereas in the ANOVA of temperature, all the parameters are found to be significant.

In MQL grinding process, the percentage of nanoparticles in the MQL and table feed is found to be significant in ANOVA of surface roughness, whereas in the ANOVA of temperature, except nanoparticles remain parameters are found to be significant.

The surface roughness is found to be minimum at 4% of nanoparticles in MQL, cutting speed of 22.92 m/sec, depth of cut of 10µm and 12 m/min of feed rate. While cutting fluids are used along with nanoparticles, a few of nanoparticles deposited on the wheel surface and perform additional fine machining and results in enhancement of surface finish.

The temperature is found to be minimum at 4% of nanoparticles in MQL, cutting speed of 9.166 m/sec, depth of cut of 10µm and 5 m/min of feed rate. Due to low thermal conductivity of nanoparticles in the cutting fluid, there is no much improvement in the thermal conductivity of cutting fluid.

A multi-response optimization is carried out for optimization of process parameters for minimum surface roughness and temperature. The optimal values of % of Nanoparticles, cutting speed, table feed and depth of cut are found to be 0.3636%, 9.166m/s, 7.12m/min and10µm respectively.

![Year 2017 Global Journal of Researches in Engineering ( ) Volume XVII Issue VII Version I A Desirability is a measure of the effectiveness of optimization using individual desirability function (d) and 1. The maximum value of desirability indicates the closer the predicted response value to the desired response [21]. Composite desirability function (D). The values of D and d are calculated between 0 to 1.](https://engineeringresearch.org/index.php/GJRE/article/download/1697/version/100909/1-Experimental-Investigation-of-Surface_html/19886/image-4.png)

| S. No. | Elements | Percentage |

| 1 | Carbon | 0.37 -0.44 % |

| 2 | Sulphur | 0.05% max |

| 3 | Manganese | 0.6 -0.9 % |

| 4 | Phosphorus | 0.04% max |

| 5 | Iron | Balance |

| Factors | Level1 Level2 Level3 | Level4 | ||

| Cutting speed, m/sec | 9.166 | 13.75 | 18.33 | 22.97 |

| Depth of cut, um | 10 | 20 | 25 | 30 |

| Table feed, m/min | 5 | 8 | 12 | 15 |

| MQL with Nano particles | 0 | 1 | 2 | 4 |

| Vegetable oil | Canola oil | |||

| Nanoparticles | 40 nm | |||

| Grinding Machine | Great Precision Oil Dip Surface Grinder |

| Workpiece material | HC-HCr steel |

| Size of wor k p iece | l20 x 60 x 25mm |

| Grinding wheel | Al 2 O 3 dia of wheel 175 mm width of 12.7mm width |

| Flow rate of vegetable oil | 25ml/hr at an air pressure of 1.8bar |

| Thermocouple used | k-type |

| Exp. | Design of Experiments | Ra | Temp | |||

| No. | % of wt. | CS | TF DOC | (µm) | (ºC) | |

| 1 | 0 | 9.166 | 5 | 10 | 0.94 | 108 |

| 2 | 0 | 13.75 | 8 | 20 | 0.85 | 182 |

| 3 | 0 | 18.33 12 | 25 | 0.92 | 233 | |

| 4 | 0 | 22.97 15 | 30 | 1.4 | 274 | |

| 5 | 1 | 9.166 | 8 | 25 | 0.92 | 133 |

| 6 | 1 | 13.75 | 5 | 30 | 0.83 | 172 |

| 7 | 1 | 18.33 15 | 10 | 0.86 | 196 | |

| 8 | 1 | 22.97 12 | 20 | 0.85 | 197 | |

| 9 | 2 | 9.166 12 | 30 | 0.92 | 164 | |

| 10 | 2 | 13.75 15 | 25 | 0.9 | 217 | |

| 11 | 2 | 18.33 | 5 | 20 | 0.8 | 181 |

| 12 | 2 | 22.97 | 8 | 10 | 0.73 | 182 |

| 13 | 4 | 9.166 15 | 20 | 0.86 | 150 | |

| 14 | 4 | 13.75 12 | 10 | 0.8 | 175 | |

| 15 | 4 | 18.33 | 8 | 30 | 0.79 | 192 |

| 16 | 4 | 22.97 | 5 | 25 | 0.69 | 190 |

| Year 2017 |

| 4 |

| I |

| Journal of Researches in Engineering ( ) Volume XVII Issue VII Version A |

| Global |

| Source | Sum of Squares | Df | Mean Square | p-value (Prob>F) |

| Model | 0.76 | 3 | 0.25 | 0.0004 |

| A-Cs | 1.840E-003 | 1 | 1.840E-003 | 0.7629 |

| B-Feed | 0.083 | 1 | 0.083 | 0.0598 |

| C-Doc | 0.67 | 1 | 0.67 | 0.0001 |

| Residual | 0.23 | 12 | 0.019 | |

| Cor | 0.99 | 15 |

| Source | Sum of Squares | Df | Mean Square | p-value (Prob>F) |

| Model | 3.253E+005 | 3 | 1.084E+005 0.0001 | |

| A-Cs | 33503.33 | 1 | 33503.33 | 0.0137 |

| B-Feed | 37130.28 | 1 | 37130.28 | 0.0103 |

| C-Doc | 2.546E+005 | 1 | 2.546E+005 0.0001 | |

| Residual | 48315.83 | 12 | 4026.32 | |

| Cor | 3.736E+005 | 15 1.084E+005 | ||

| Source | Sum of Squares | Df | Mean Square | p-value (Prob>F) |

| Model | 0.21 | 3 | 0.054 | 0.0305 |

| A-% Nano | 0.10 | 1 | 0.10 | 0.0187 |

| B-Cs | 1.021E-004 | 1 | 1.021E-004 | 0.9320 |

| C-Feed | 0.075 | 1 | 0.075 | 0.0368 |

| D-Doc | 0.037 | 12 | 0.037 | 0.1247 |

| Residual | 0.15 | 15 | 0.013 | |

| Cor Total | 0.36 |