1. Introduction

he use of natural fats and oils by man date back to very ancient times.Fats and oils have specific chemical properties which make them very useful as lubricants. Vegetable, animal and marine sourcesare the main sources of natural fats and oils and their chemical naturewouldmake them very useful in many applications. Fats and oils are naturally occurring substancesthat consist predominantly of mixtures of fatty acidesters derived glycerol [1].

Vegetable oils are a renewable energy source in that they are created from plants that can be regrown and they consist mainly of tri-esters of straight-chained, mostly unsaturated fatty acids with glycerol. [2,3].What distinguish these vegetable oils is that they have higher levels of biodegradability and lower toxicity than conventional mineral or synthetic oils. Therefore, these biofuels can be utilized with ease in cars and other places since they do not require muchchemical or physical property changes. Many scientists believe that the use of biofuels as carbon neutral would be beneficial to the environment since the carbon produced when burning them is offset by the carbon consumed by the plants they came from. Research suggests that using biofuels would help in reducing carbon emissions by 50-60%. They are other benefits for using vegetable oilsas biofuels, for example biofuels from vegetable oils have a very low volatility, good high lubricity and high viscosity index, as well as lower cost than most synthetic oils [4,5,6]. Many researches have pointed out that the use of biofuels as lubricants has its own drawbacks for example using land for biofuel crops this will mean less land for food production. Also, vegetable oils have low thermal and oxidative stabilities, narrow viscosity range and higher pour points than both mineral or synthetic oil-based lubricants, that's why vegetable oils have a limited use as lubricants and their use in the industry is not yet extensive [7,8,9].

? Lubricant's performance for a certain systemis a very important characteristic that should be quantified and it can be determined by carrying out specific experimental tests. The lubricity of a substance is not a material property whichcannot be measured directly. The lubricity of the fuel is an indication of the amount of wear or scarring which happens between two metal parts covered with the fuel as these metal parts come in contact against each other. Low lubricity fuel may cause high wear and scarring and high lubricity fuel may provide reduced wear and longer component life. Biofuels such as vegetable oils are used as lubricants, specifically, when there is a leakage of equipment or where the system is designed tofunction by loss lubrications. Systems, such as:Open gear lubricants, arming, mining, and forestry equipment, hydraulic oils etc. The viscosity index (VI) is a very important property of the biofuels, which is a relative measurement in change of base fluid viscosity between 40°C and 100°C. The viscosity index indicates the change in viscosity over an extended temperature range. It is well documented that vegetable oils display very high viscosity indices (VI) compared to mineral oils. Also, vegetable oils can afford higher flash points as compared to mineral oils [10].

Vegetable oils are high-performance base oils which are extracted from coconut, palm and soy.These vegetable oilsare considered as lubricants and they are compatible withadditives currently used in thelubrication industry. These vegetable oils have many advantages such as: low cost, acceptable low-temperature properties, and acceptable oxidative and thermalstability. Fattyacids are normally contained in some vegetable oils and it would improve its lubricity, forexample fatty acids that exist in the palm oil, tend to cling to metal surfacesmore effectively than mineral oils andtherefore provide improved lubricity.The research main point is using biofuels as light lubricant with low heat applications like joints, track, bearings. So,the experiments were carried out at various temperatures and the results showed thatoil viscosity will change with temperature, so the temperature range is the main point. The experimental data obtained of vegetable oils showed that low values of kinematic viscosities at 40°C but higher values of kinematic viscosities at l00 O C (12) with higher viscosity index range from 203 to 263. Also, vegetable oilsviscosity showed much variation over temperature range and have instability and poor temperature properties. Results showed that corn oil and soybean oil were more viscous at high temperatures than synthetic oil.

2. II.

3. The SVM Machine

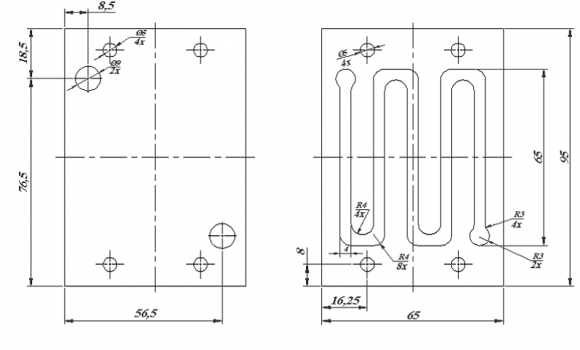

Absolute and kinematic viscosity measurements procedure were used to find the viscosity with temperature relationship from different bio-fuels. The device shown in figure (1) is the SVM 3000 and its measuring process depends on torque and speed measurements. The SVM 3000 uses a rotating magnet which produces eddy current field. The first group of results showed the relation between temperature and oil specific gravity as shown in figure (3). The results show that as the temperature increases a decrease in the Corn, Palm, and Almond oils specific gravity was noticed. Therefore, it can be deduced that the specific gravity of these vegetable oils (density) is dropped with increasing temperature.

4. Figure (1): SVM 3000 device

5. Figure (3): Bio Fuel (oils) Specific gravity vs. temperature

The relation between vegetable oils specific gravity and temperature is linear, by using regression the linear relation is obtained for all oils (Corn, Palm, and Almond). In figure (4) all types of Bio fuels have the same linear inclination (slope), so the behavior of the tested Bio-fuels with temperature is the same if the view point is the oil density or specific gravity. Figure (6) shows mathematical modelling of Palm oil with temperature, the polynomial of absolute viscosity is of order six, also figures (7) and (8) show mathematical model of Corn and Almond oil, the coefficients of all oil polynomials are obtained.

6. IV.

7. Conclusions

Different vegetable oils were tested using SVM3000 viscosity machine, this paper aims to create viscosity modelling of these vegetable oils. The tested oils are Palm, Almond, and Corn, the experimental results obtained are oil absolute viscosity, kinematic viscosity, and specific gravity. A sixth order polynomial for absolute viscosity was obtained to show the oil mathematical model, also a linear equation is created using Excel software for the tested vegetable oils specific gravity with temperature.

| Canola oil | Hydraulic oils, tractor transmission fluids, metalworking fluids, food grade lubes, |

| penetrating oils, chain bar lubes | |

| Castor oil | Gear lubricants, greases |

| Coconut oil | Gas engine oils |

| Olive oil | Automotive lubricants |

| Palm oil | Rolling lubricant,-steel industry, grease |

| Rapeseed oil | Chain saw bar lubricants, air compressor-farm equipment, Biodegradable greases |

| Safflower oil | Light-colored paints, diesel fuel, resins, enamels |

| Linseed oil | Coating, paints, lacquers, varnishes, stains |

| Soybean oil | Lubricants, biodiesel fuel, metal casting/working, printing inks, paints, coatings, soaps, |

| shampoos, detergents, pesticides, disinfectants, plasticisers, hydraulic oil | |

| Jojoba oil | Grease, cosmetic industry, lubricant applications |

| Crambe oil | Grease, intermediate chemicals, surfactants |

| Sunflower oil | Grease, diesel fuel substitutes |

| Cuphea oil | Cosmetics and motor oil |

| Tallow oil | Steam cylinder oils, soaps, cosmetics, lubricants, plastics |