1. Introduction

Abstract-In this study, Tectona grandis was pyrolysed in a fixed-bed cylindrical-typed pyrolysis reactor for bio-oil production at a reaction temperature between 410 o C and 530 o C . The product yields were collected at an interval of 30 o C. The highest product yield occurred at 500 o C. Proximate and ultimate analyses were carried out using iso-conversional methods and GC-MS respectively.

The proximate analysis of the raw sample showed that the moisture content, volatile matter, fixed carbon and ash content were 6.4%, 77.94%, 14.4%, 1.26% respectively while ultimate analysis of the raw materials showed that the content of carbon, hydrogen, nitrogen, sulphur and oxygen were 49.85%, 4.47%, 0.65%, 0.52%, and 44.51% respectively. The ultimate analysis of bio-oil showed that the content of carbon, hydrogen, nitrogen, oxygen and sulphur were 43.56%, 6.25%, 0.62%, 48.89%, 0.68% respectively. The HHV and LHV of the bio-oil obtained were 35.65 MJkg -1 and 17. 35 MJkg -1 respectively. The GC-MS analysis of the bio-oil of T. grandis showed the presence of 21 compounds amounted to 98.9%. The most abundant component was palmitic acid (15.0%). The other major compounds present in the bio-oil were oleic acid (12.3%), cis-1, 9-hexadecadiene (12.0%), cis-10-pentadecen-1-ol (12.0%), 9-octadecenal (12.0%), trans-2-octadecadecen-1-ol (12.0%), myristic acid (5.0%) and stearic acid (5.0%). The bio-oil was active against all the tested bacteria with high zones of inhibition (14.0-30.0 mm). This study established that bio-oil should not only be used as a fuel but can also be purified and served as inhibitor of biofilm and bio-corrosion. lack of effective waste management systems. However, sustainable energy can be generated from these wastes thereby putting an end to environmental pollution generated from them (Khajuria et al., 2008;Popoola et al., 2013;Anyanwu and Adefila, 2014;Montevecchi, 2016). Pyrolysis of biomass is listed among the most promising technologies able to overcome the global challenges arising from a shortage of fossil fuels, increasing demands for energy, and environmental concerns as well (Ilnicka et al., 2014). Means of transforming wastes into useful form of energy by pyrolysis into liquid fuel should be considered very important as sources of energy. Therefore, waste would be more readily useful and environmentally acceptable (Rahim et al., 2013;Hossain et al., 2014). Pyrolysis is a thermochemical process that transform biomass into liquid, charcoal and non-condensable gases by heating the biomass in the absence of air (Jahirul et al., 2012; Verma et al., 2012;Lohri et al., 2016). Pyrolysis is the chemical decomposition of organic matter by heating in the absence of oxygen (Jahirul et al., 2012;Akinola, 2016).

Pyrolysis has attracted more interest in producing liquid fuel because of its advantages in storage, transport and versatility in applications (Jahirul et al., 2012;Wijayanti et al., 2016). The potential of biooil production from wood residues using pyrolysis is of great important, it is superiority to other systems of waste-to-energy conversion as it operates at atmospheric pressure and modest temperatures with yields of bio-oil exceeding 70 wt % (Popoola et al., 2013;Balogun and Salami, 2016). Biomass is rapidly heated to a high temperature in the absence of oxygen in the fast pyrolysis process (Jahirul et al., 2012). Bio-oil can be produced from wood, bark, agricultural wastes, nuts, seeds, algae, grasses, forest residues, and cellulose and lignin. The nature of the feed stocks influences the properties of the obtained bio-oils (Kato et al., 2016). Bio-oil has a lower sulphur and nitrogen content compared with that in fossil fuels. Therefore, bio-oil from fast pyrolysis can be used in static applications, such as in boilers, diesel engines for power generation and industrial boilers and kilns to replace fossil fuels. It can be used as a source of high quality chemicals (Hou et al., 2016;Wang et al., 2016). Moreover, bio-oil can be used as an alternative fuel directly or after application of some purifying and improving processes (Vamvuka, 2011;Hou et al., 2016). iomass is a promising eco-friendly alternative source of renewable energy in the context of current energy scenarios. It can be converted to bio-fuel through different thermal, biological and physical processes. Biomass has being gaining intense attention as a renewable energy source to mitigate global warming, due to environmental concerns over excessive fossil fuel usage (Balat and Kirtay, 2010;Panwar et al., 2011;Rahim et al., 2013;Hossain et al., 2014;Fadzil et al., 2016;Swenson, 2016). The problem of solid waste disposal has become an alarming environmental problem in many countries with B Compositional analysis was conducted using both observation and instrumental analytical methods to obtain the extractive and lignin contents according to ASTM D1108-96 and ASTM D1106-96, respectively (Balogun et al., 2014).

2. c) Heating Values

The heating values were determined according to ASTM D5865, standard test method for gross calorific value of coal and coke on dry basis using the oven dried samples. The PAAR 1341 oxygen bomb calorimeter with Fast Pyrolysis of Tectona grandis Wood for Bio-Oil: Characterization and Bactericidal Potentials

The bio-corrosion is the deterioration of a materials caused by microorganisms that influence production biofilm and corrosion by changing the electrochemical conditions on the metal or solution interface. Biofilm and bio-corrosion are prevented or delayed by inhibiting the growth or metabolic activities of the microorganisms through biocides, radical scavenging, antioxidation processes and changing the environment in which the corrosion process occurs (Moura et al., 2013). Some natural products have been described as potential substances in controlling the growth of several microorganisms aiding biofilm formation, bio-corrosion and wearing of materials. Plant origin biofilm and corrosion inhibitors are biodegradable and do not contain heavy metals or other toxic compounds (Rani and Basu, 2011; Moura et al., 2013).

Tectona grandis Linn. commonly known as teak belongs to verbanaceae family, it is one of the most famous timber in the world and is renowned for its dimensional stability (Neha and Sangeeta, 2013; Ramesh and Mahalakshmi, 2014). T. grandis is a medium-size timber. The wood is often dull yellowish when freshly cut but it turns golden brown or sometimes dark greyish-brown with time, often streaked greyish or blackish (Louppe, 2005;Sholadoye et al., 2016). It is a tropical hardwood species highly prized by the wood industries due to its superior mechanical and physical properties, as well as its pleasing aesthetic appearance (Sanwo, 1990;Kjaer et al, 1999;Sholadoye et al., 2016). The plant is commonly used for furniture making and as building materials in Africa. It forms large percentage of wastes and constituting nuisance to the environment (Adamu et al., 2014). Medicinally, it has various pharmacological activities (Neha and Sangeeta, 2013). The dyes obtained from T. grandis may be alternative sources to synthetic dyes for the dyeing of natural silk and cotton (Bhuyan et al., 2004;Bhuyan and Saikia, 2005). Leaves of T. grandis contained mainly anthraquinone moieties in their molecules (Nidavani and Mahalakshmi, 2014). Better management of the wastes from wood industries utilizing T. grandis could be achieved by producing clean energy from the materials. This study aimed at investigating the physical and chemical characterization of wood bio-oil from fast pyrolysis of T. grandis and to evaluate its bactericidal properties against bio-corrosion aiding bacteria.

3. II.

4. Materials and Methods

5. a) Biomass Sample and Pyrolysis Procedure

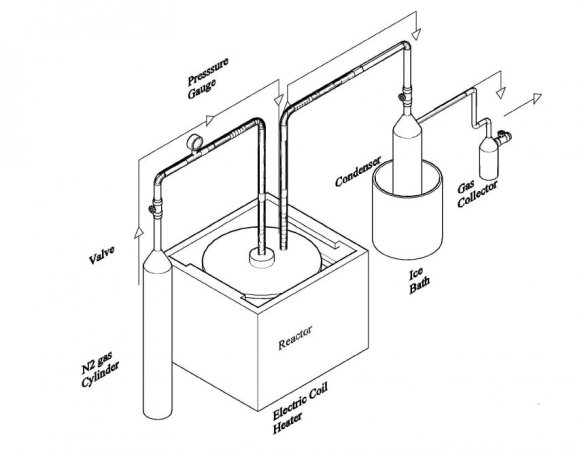

The wood sample used in this study was obtained from Ota, Nigeria. It was air dried and pulverized to a particle size of 500 µm using Philip milling machine. Pyrolysis was carried out in a fixed-bed cylindrical-typed carbon steel 300 ml reactor heated by a 4 kW furnace with automatic temperature control equipped with a condenser, ice bath and gas collector (figure 1). After been dried to 7% moisture content, 100g the sawdust was used as raw material for the production of bio-oil in a lab-scale fluid-bed fast pyrolysis procedure. Fast pyrolysis of the sawdust was then performed at 410-530 °C at interval of 30 o C in a nitrogen atmosphere with a pyrolysis product residence time of 1.3 s. The obtained bio-oil was kept at 4 °C in a refrigerator until further analysis . Year 2017

A © 2017 Global Journals Inc. (US)benzoic acid pellets was used to determine the gross calorific value (HHV) while the net calorific value (LHV) was calculated using wt% of hydrogen resulting from elemental analysis of the sample (Okoroigwe and Saffron, 2012).

6. d) GC-MS Analysis

The bio-oil was analysed using Shimadzu GC-MS-QP2010 Plus (Japan). The separations were carried out using a Restek Rtx-5MS fused silica capillary column (5%-diphenyl-95%-dimethylpolysiloxane) of 30 m× 0.25 mm internal diameter (di) and 0.25 mm in film thickness. The conditions for analysis were set as follows; column oven temperature was programmed from 60-280 °C (temperature at 60 °C was held for 1.0 min, raised to 180 °C for 3 min and then finally to 280 °C held for 2 min); injection mode, Split ratio 41.6; injection temperature, 250 °C; flow control mode, linear velocity (36.2 cm/sec); purge flow 3.0 ml/min; pressure, 56.2 kPa; helium was the carrier gas with total flow rate 45.0 ml/min; column flow rate, 0.99 ml/min; ion source temperature, 200 °C; interface temperature, 250 °C; solvent cut time, 3.0 min; start time 3.5 min; end time, 24.0 min; start m/z, 50 and end m/z, 700. Detector was operated in EI ionization mode of 70 eV. Components were identified by matching their mass spectra with those of the spectrometer data base using the NIST computer data bank, as well as by comparison of the fragmentation pattern with those reported in the literature (Ololade et al., 2014).

7. e) Bactericidal Activities

The antibacterial potentials of the bio-oil were evaluated by agar-well diffusion method against biofilm and bio-corrosion aiding gram-positive bacteria (Micrococcus varians, Streptococcus agalactiae and Staphylococcus aureus) and gram-negative bacteria (Escherichia coli, Klebsiella pneumoniae, Proteus mirabilis, Pseudomonas aeruginosa, Serratia marcescens and Salmonella typhimurium). The bacteria isolates were sub-cultured in Nutrient agar and incubated at 37 o C for 24 hours. All the cultured bacteria were adjusted to 0.5 McFarland standards, 20 ml of sterilized Nutrient agar medium was poured into each Petri dish aseptically and plates were swabbed with diameter wells were bored into the seeded agar plates, and these were loaded with different concentrations (1000, 500 and 250 µgml -1 ) of the bio-oil solution. The plates were allowed to stay in a refrigerator for 1 hour to allow proper diffusion of the bio-oil solution into the medium and incubated at 37 o C for 24 hours before visual assessment of the inhibition zones. Antimicrobial activities were expressed as inhibition diameter zones in millimetre (mm). Synthetic antibiotics was used as control (Ololade et al., 2014). The colour of the obtained wood bio-oil from T. grandis was golden yellow with slight pungent odour. The elemental composition, moisture content, density, ash content, viscosity, pH, lower heating value (LHV) and higher heating values (HHV) of the feed materials and bio-oil were given in Table 1 and 2. Table 1 showed that high energy values could be obtained from feed material. Compared to results gotten from analyses of bio-oils from the other sources, the results indicated that the bio-oil used in this study contained more carbon (43.56%) and oxygen (48.89%). The low nitrogen (0.62%) and sulphur (0.68%) showed that the bio-oil has low pollutant effect which showed that they are ecofriendly bio-oil. Moreover, HHV and LHV were 35.65 and 17.35 MJkg -1 respectively, were also greater than other bio-oil reported Rahim et al., 2013;Hossain et al., 2014). The moisture content and viscosity of the bio-oil were similar to those of the other bio-oils , indicating that the biooil could be easily handled. The moisture content could be traced to moisture in feed sample and water of dehydration reactions, the pH and ash content was at the threshold range for bio-oils from biomass Kato et al., 2016). The pH of this bio-oil could be neutralized in other to prevent corrosion and other reactions of the bio-oil when used for engines and boilers (Sukhbaatar et al., 2009;.

8. III.

9. Results and Discussion

10. b) Effect of Temperature on the Product Yields

The products (bio-oil, pyro-gas and char) yields at different pyrolysis temperature were shown in figure 2. The bio-oil yield increases with increase in temperature up to 500 o C. Above 500 o C, there is decrease in the yield. This is because bio-oil secondary reactions yield more gas and char at temperature Above 500 o C, there was decrease in the yield, because bio-oil secondary reactions yield more gas and char at temperature above 500 o C. This is similar to what was obtained from the pyrolysis of other biomasses (Fagbemi et al., 2001). Char yield decreased from 35.0 wt% to 17.0 wt% with increase pyrolysis temperature. This was due to increase rate of primary decomposition at high temperature or through secondary decomposition of the solid residue. The obtained result was similar to what was gotten from other bio-oils (Gheorghe et al., 2010;. It was observed that as temperature increased from 410-530 o C the bio-gas yield increased from 12.0 wt% to 31.5 wt%.

11. c) Chemical Composition of the Wood Bio-oil

The GC-MS analysis of the bio-oil of T. grandis showed the presence of twenty-one compounds amounted to 98.9%. The most abundant component was palmitic acid (15.0%). The other major compounds present in the bio-oil were oleic acid (12.3%), cis-1, 9-hexadecadiene (12.0%), cis-10-pentadecen-1-ol (12.0%), 9-octadecenal (12.0%), trans-2octadecadecen-1-ol (12.0%), myristic acid (5.0%) and stearic acid (5.0%). The GC-MS indicated the presence of hydrocarbons, fatty acids, alcohols, esters, ethers, ketones, furan and phenolic compounds.

IV.

12. Conclusion

In this study, the potentials of waste-to-energy system in Nigeria had been assessed. The obtained results of this study showed that the bio-oil produced met the qualities of other liquid products from other energy classified biomass. This showed that the obtained bio-oil could be a good source of energy for the heating of reactor chambers and could be a good substitute for coal in power generation. This study

13. d) Bactericidal activities

The antimicrobial screening of the T. grandis wood bio-oil gave wide inhibition zones against the tested biofilm and bio-corrosion aiding bacteria strains compared with the synthetic antibiotics. The inhibition zones of the bio-oil (20-30 mm) were greater than that of gentamicin (Gen) a synthetic antibiotics (15-20 mm) except for S. marcescens (30 mm). The investigated bio-oil of T. grandis could be an agent of prevention, inhibition and elimination of microorganisms aiding formation of biofilm and bio-corrosion of industrial materials (Rani and Basu, 2011; Moura et al., 2013). Biooils from this plant can also potentially be used in drug formulation against multi-drug resistant bacteria, food processing and preservation due to its large spectrum of biological properties, low environmental risk and low cost .

established the fact that understanding the compositions of bio-oils will add to their use in thermochemical conversion platforms, as this information will be extremely important in evaluating the bio-oils' stabilities, properties, and toxicities. The studied bio-oil has the potential of being used as alternative eco-friendly and cheap natural product as inhibitor of biofilm, bio-corrosion and wear materials, also as therapeutic agent for human and animals. Conflict of Interest: The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

| Proximate analysis (wt. %) | Ultimate analysis (wt. %) | ||

| Moisture | 6.40 | Carbon | 49.85 |

| content | |||

| Volatile | 77.94 | Hydrogen | 4.47 |

| matter | |||

| Fixed carbon | 14.40 | Nitrogen | 0.65 |

| Ash | 1.26 | Sulphur | 0.52 |

| Oxygen | 44.51 | ||

| HHV(MJkg -1 ) | 17.05 | ||

| LHV(MJkg -1 ) | 14.55 | ||

| Physical property | Ultimate analysis | (wt.%) | |

| Moisture content (%) | 28.92 | Carbon | 43.56 |

| Density(g cm -3 ) | 51.24 | Hydrogen | 6.25 |

| Ash (%) | 0.7 | Nitrogen | 0.62 |

| Dynamic Viscosity (cp) | 53.25 | Oxygen | 48.89 |

| pH | 2.62 | Sulphur | 0.68 |

| HHV(MJkg -1 ) | 35.65 | ||

| LHV(MJkg -1 ) | 17.35 |

| Compound | Retention Index | Percentage Composition |

| luprosil | 676 | 3.0 |

| 2,5-dimethylfuran | 732 | 2.4 |

| 1,4-dimethyl-1H-pyrazole | 804 | 0.8 |

| 2-methylbutyric acid | 811 | 1.0 |

| 3-octene | 824 | 0.8 |

| 5-methyl-3-methylene-5-hexen-2-one | 887 | 0.5 |

| 4,5-dimethyl-1H-imidazol | 927 | 0.8 |

| cyclooctane | 959 | 0.4 |

| corylone | 972 | 0.4 |

| 3-methylcyclopentane-1,2-dione | 1003 | 0.4 |

| methyl-1-cyclohexenyl ketone | 1027 | 1.6 |

| o-guaiacol | 1090 | 0.5 |

| 2-nitroethylpropionate | 1067 | 1.0 |

| cis-1,9-hexadecadiene | 1610 | 12.0 |

| cis-10-pentadecen-1-ol | 1763 | 12.0 |

| myristic acid | 1769 | 5.0 |

| palmitic acid | 1968 | 15.0 |

| 9-octadecenal | 2007 | 12.0 |

| trans-2-octadecadecen-1-ol | 2061 | 12.0 |

| stearic acid | 2167 | 5.0 |

| oleic acid | 2175 | 12.3 |

| Percentage Total | 98.9 |

| Bio-oil | Synthetic | |||

| Antibiotic | ||||

| Gen | ||||

| Conc. (µgml -1 ) | 1000 | 500 | 250 | 10µg |

| Organisms | ||||

| E. coli | 24 | 25 | 27 | 17 |

| K. pneumoniae | 30 | 30 | 30 | 15 |

| P. aeruginosa | 20 | 20 | 20 | 16 |

| P. mirabilis | 21 | 21 | 22 | 16 |

| S. typhimurium | 20 | 23 | 23 | 18 |

| S. marcescens | 22 | 22 | 14 | 30 |

| M. varians | 27 | 27 | 24 | 18 |

| S. agalactiae | 24 | 24 | 27 | - |

| S. aureus | 23 | 25 | 28 | 20 |

| Keynote: Resistant (--), not sensitive (<8 mm), sensitive (9-14 mm), very sensitive, (15-19 mm) and ultrasensitive (>20 | ||||

| mm) | ||||