1. I. Introduction

ortable drinking water is a core component of daily human existence. Though three quarter of the earth's surface is covered by water, 97% of available water sources are brackish and microbiologically unsafe. Only 1% of earth's water is safe for drinking [1].Access to safe water and sanitation is a major challenge in Nigeria. Water and Sanitation coverage rates in Nigeria are amongst the lowest in the world. Nigeria is currently not on track to reach the MDG targets of 75% coverage for safe drinking water and 63% coverage for basic sanitation by the year 2015 [2].

A good method of obtaining portable drinking water is by distillation. Most conventional distillation methods such as reverse osmosis, membrane distillation, multistage and multiple effect distillation are energy intensive, expensive and require a high level of technical skill to operate. Therefore, solar distillation is an ideal solution and the simplest technique among other treatment processes suitable for supplying small Communities in rural and remote areas with portable drinking water [3,4].

The basic principles of solar water distillation are simple yet effective, as operation of solar still is similar to the way nature makes rain that includes two processes, namely evaporation and condensation [5]. The sun's energy heats brackish water in a basin to the point of evaporation in an air tight environment. As the water evaporates, water vapor rises, condensing on the cooler surface of a transparent cover for collection. This process removes impurities such as salts and heavy metals as well as eliminates microbiological organisms. The end result is water cleaner than the purest rainwater [1].

Solar stills are generally classified into two types: active and passive. In active solar still the water coming into the basin is preheated externally in order to increase the water temperature in the basin, which will inevitably increase the evaporation rates. Passive solar still are the conventional solar stills (CSS).Direct solar energy falling on the basin effective area is the only source of thermal energy. The heat collection, evaporation and condensation all occur within one system. Simple modifications within the basin are used to enhance the productivity [6].

Solar still are the ideal solution for standalone water distillation systems in rural and isolated areas. Although solar stills havelow productivities, they are the most sustainable water productionmethod in these areas. The current research focus is how to improve the poor productivity of these systems.

The performance of solar still is generally expressed as the quantity of water produced by basin area in a day. The quantity of water produced by the solar still is affected by design, operational and ambient conditions. The ambient conditions cannot be controlledby humans as they are dependent on meteorological parameters. The design conditions which include assembly materials can be easily manipulated by humans to affect the production rate.

Phase change materials (PCM) can improve the productivity of solar stills, when applied in latent heat systems. This method relies on heat being release from the bottom of stills [7]. The solar radiation is transmitted through the transparent cover and isabsorbed by the basin and PCM thereby increasing their temperatures. Part of the energy absorbed by the basin is transferred by convectionto the basinwater and the other transferred by conduction to the coolerPCM under the basin. As the PCM is heated, heat is first stored as asensible heat until the PCM reaches its melting point. At this time, thePCM starts to melt and after complete melting of the PCM, the heatwill be stored in the melted PCM as a sensible heat. Improving the performance of CSS using phase change material (PCM) as heat storage media in solar still have been previously studied. [8] studied two cascade solar stills constructed with and without latent heat thermal energy storage system (LHTESS). Paraffin wax was selected as the phase change material (PCM) which acts as a LHTESS. Thermal performances of the stills were compared in typical sunny and partially cloudy days. Results showed that the total productivity is nearly the same for both stills in a typical sunny day. However, for a partially cloudy day, the still with LHTESS has a significantly higher productivity. [4] developed a theoretical model for a still with and without phase change material (PCM). They concluded that the daily productivity of the still with and without the PCM was 6.7 and 5.1 kg/m 2 /day respectively. The results showed that the productivity of the still with PCM was theoretically 31% higher than that of without PCM. [9] studied the effect of minimum depth of water with different storage materials in the basin. The performance of the solar still was compared with different types of energy storing materials like quartzite rock, washed stone, cement block pieces, red brick pieces and iron scraps. It was observed that, the still with 3/4 in. sized quartzite rock is the effective basin material. The transient performance of a stepped solar still with built-in latent heat thermal energy storage was studied by [10]. He concluded that the still has an efficiency of 57% and the total yield is about 4.6 L/day/m 2 . A mathematical model for a single basin-single slope solar still with and without PCM under the basin liner of the still was presented [7]; numerical calculations were carried out using stearic acid as a PCM, on typical summer and winter days. The results of the study showed a productivity of 9.005 (kg/m 2 day) with a daily efficiency of 85.3% has been obtained e XV Issue IV Version I ( ) A Distillate Yield Improvement using a Parabolic Dish Reflector Coupled Single Slope Basin Solar Still with Thermal Energy Storage using Beeswax compared to 4.998 (kg/m 2 day) when the still was used without the PCM. A concentrator-coupled hemispherical single-slope solar still solar still with and without phase change material (PCM) were studied experimentally by [11]. Results indicate that the effect of thermal storage in the concentrator-coupled hemispherical basin solar still increases the productivity by 26%.

In this paper, a parabolic reflector-coupled single slope basin solar still is integrated with beeswax as a PCM beneath the basin liner of the still. Because of the high melting point of beeswax, heat from the parabolic dish reflector apart from direct solar radiation was used. The distillate yields, with and without PCM effect are reported.

2. II. Material and Method

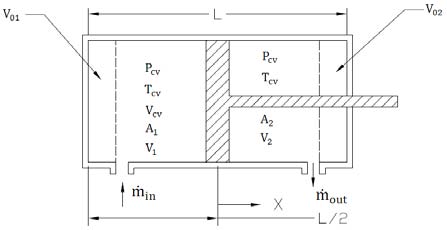

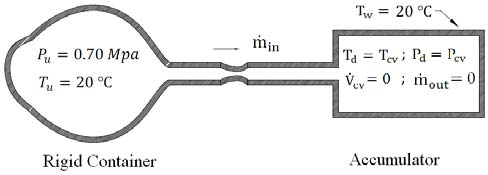

A schematic and pictorial diagram of the parabolic reflector dish solar still with phase change material (PCM) as a heat storage medium is shown in Fig. 1-2. The basin area of the still is 0.3 m 2 , fabricated from a black painted aluminum sheet of thickness 0.2 cm leaving a3 cm gap under the horizontal portion of the basin liner. This gap is loaded with the 14 kg of PCM. Waste beeswax which is a by-product of the local honey processing industry is used as the PCM because of its low cost, wide availability and stability in the working range. The under of the solar still is covered with another aluminum sheet of thickness 0.2 cm painted black on the side facing the parabolic concentrator. Table 1 summarizes the thermo-physical properties of beeswax (Ravi Ramnanan-Sing, 2012). The sides of the basin are insulated by 3 cm layer of rockwool contained in a wooden frame of 1 cm thickness to prevent heat losses. Rookwool which have a thermal conductivity of 0.038 W/m 2 K is used as an insulator on the still sides.The cover of the still is made up of 0.3 cm thick simple window glass, making an angle of 27.9 0 . Optimum slope of collector for Makurdi city was calculated using angle of solar declination (?), number of days, latitude at test site, and angle of incidence from the following equation [12]:

Slope of collector (??) is calculated by using the following formula:

?? = (?? ? ??)(1)Where, ?? = Latitude at test site, = 7.7 0 N 2. This optimum angle is about 27.9° for Makurdi which is located in the middle belt region of Nigeria. The fresh water is collected in an aluminum channel fixed at the lower end of the glass cover. Various temperatures like ambient (T amb ), water (T w ), air (T a ), and condensing glass cover inner-outer surfaces (Tig and Tog) were recorded hourly between the hours of 9:00 am-5:00 pm using K-type thermocouples. Table 3 summarizes accuracies and error percentage of variousmeasuring instruments used inthe experiment.The solar radiation transmitted through the glass cover and basin water is absorbed by the basin liner; hence, its temperature increases. Part of thermal energy is transferred by convection to the basin water and the other will be transferred by conduction to the PCM beneath the basin liner. A 0.2 cm aluminum sheet painted black on the parabolic collector facing side is used as cover under the solar still. The solar parabolic concentrator focuses solar radiation under the solar still, which is transmitted by conduction to the PCM, heat from the parabolic solar concentrator is first stored as a sensible heat till the PCM reaches its melting point irrespective of the liner temperature. The PCM melts before the temperature of the liner rises to the melting temperature of the PCM. By the time, the PCM starts to melt and after complete melting of the PCM, the heat will be stored in the melted PCM as a sensible heat. The combined effect of the sun's radiation and concentrated flux from the parabolic dish reflector speeds up the melting of the PCM. Afternoon, when the solar radiation decreases, the PCM is kept molten by the heat from the parabolic concentrator and will continue to transfer heat to the basin liner and from the latter to the basin water until the PCM completely solidified. In other words, the PCM will act as a heat source for the basin water during low intensity solar radiation periods.

3. III. Results

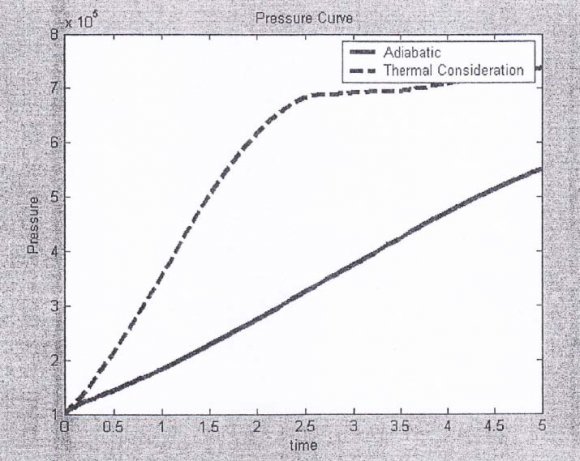

It has been proven that the productivity of a solar still is dependent on meteorological conditions of a place like solar radiation, ambient temperature etc. Fig. 3 depicts the variation of solar radiation and ambient temperature with time on 26/1/2015. Insolation is measured in the range of 580 W/m 2 to 899 W/m 2 , insolation gradually increases from early morning to 1 pm as the sun rises and then reduced towards evening due as the sun begins to set. The ambient temperature is in the range of 37.3 °C to 39.3 °C. The maximum water temperature observed was 86 °C at 1 pm. Similarly the maximum air temperature of 80 °C was measured, while the inner and outer cover temperatures were in the range of 39-73 °C and 32-63 °C, respectively. Fig. 5 shows the variation of water temperature, air temperature, inner glass temperature, and outer glass temperature with respect to time for concentrator-coupled single slope basin solar still without PCM. The maximum water temperature observed was 76 °C. Similarly the maximum air Fig. 6 shows the distillate yield with respect to time. The maximum output collected for concentratorcoupled hemispherical basin solar still with PCM was 5243 ml/m 2 /day, and 3240 ml/m 2 /day for the solar still without PCM.

4. IV. Discussion

The hourly productivity with the PCM is much higher than that without the PCM during sunrise which is characterized by increasing solar intensities. This behavior is unexpected because the PCM under the basin liner absorb heat from the liner. But in the current configuration, the parabolic dish provides concentrated heat flux to the PCM via the basin linerthereby increasing the basin water temperature as well as the productivity throughout the day and into the evening. The beeswax is melted in the morning hours due to the high intensity of solar radiation from the parabolic concentrator. It melts entirely during the charging phase from 10:00 to 11:00 h. The beeswax is kept molten by the intensity of the radiation from the parabolic concentrator even with a decrease in the ambient temperature and solar intensity. Subsequently, with a further decrease in solar intensity towards sunset, it becomes solid again releasing sensible heat into water. The still with PCM yields larger amounts of distilled water than the still without PCM because of the higher operating temperature. This high operating temperature is obtained because the stored heat from the PCM is transferred by conduction through the basin liner to evaporate the water at enough high temperature.

e XV Issue IV Version I ( ) A Furthermore, the increase in temperature noticed in the still at 16:00 to 17:00 h is due to the effect of heat released by the PCM during the discharge phase. The productivity of the concentrator coupled single slope single basin solar still with PCM was approximately 62% higher than the concentrator coupled single slope single basin solar still without PCM.

5. V. Conclusion

In this present work, parabolic concentrator coupled single slope single basin solar still was fabricated and tested in Makurdi climate conditions. Many experiments have been conducted to enhance distillate output of solar still. The performance of parabolic concentrator coupled single slope single basin solar still without PCM under the basin liner was compared with that parabolic dish reflector coupled single slope single basin solar still with PCM under the basin liner. It was observed that, on a good sunny day, the daily productivity of the parabolic concentrator coupled single slope single basin solar still with increased to 62% with PCM under basin liner of solar still. The higher temperature difference observed between the basin water and inner glass temperature is due to the absorbed energy of PCM. It is recommended to integrate latent heat energy storage system in solar stills to further enhance their productivity.

| Parameters | Symbol | Value |

| Transmittance of cover | ?? ?? | 88% |

| Emissivity of cover | ?? ?? | 0.98 |

| Wind velocity | V | 0.8 m/s |

| Density of water | ?? | 989 kg/m 3 |

| Latent heat of vaporization | ? ð??"ð??"ð??"ð??" | 2,463 kJ/kg |

| Declination angle | ?? | 20.2 0 |

| Latitude | ?? | 7.7 0 |

| S/No. | Instrument | Accuracy | Range | % Error |

| 1 | Solarimeter | ±1??/?? 2 | 0-2500W/m 2 | 2.5 |

| 2 | Digital thermometer | ±1 0 C | 0-250 0 C | 0.5 |

| 3 | K-type thermocouples | ±0.1 0 C | 0-300 0 C | 0.5 |

| 4 | Anemometer | ±0.1??/?? | 0-20 m/s | 5 |

| 5 | Measuring jar | ±10 ???? | 0-1000 ml | 10 |