1. Introduction

acility layout concerns with the optimum arrangement of departments with known dimensions in such a way that minimizes materials handling and ensure effective utilization of men, equipment and space. In the competitive world, demand is continuously increasing where resources are always limited. In industry sectors, it is important to manufacture the products which have good quality and meet customers demand. This action could be conducted under the existing resources like employees, machines and other facilities. For this reason, industrial factories need to increase their potentials in production and effectiveness to compete against their competitors. That is why; the production process needs to be set in a proper organized way that minimizes production cost with higher effectiveness. Therefore, the way of solving the problem of production is very important.

There are many techniques like quality control (QC), Pareto analysis, total quality management (TQM), control chart and plant layout are used to solve the problems concerning productivity. However, plant layout improvement could be one of the tools to response to industrial productivity improvement by the reduction of cost of manufacturing with a proper workflow in production route. For ensuring proper workflow departments are arranged in such a way that optimizes their relative placement. Sometimes, optimal placement means placing inter dependent traffic departments adjacent to one another. Knowing the nature of flow between departments and process of material flow is important.

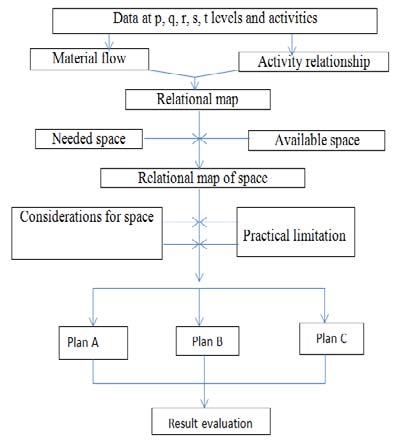

Systematic layout planning pattern (SLP) theory is used to analyze the step-by-step of layout facility from raw material storage to finish product dispatched. This method helps to develop a new plant layout with improved process flow and effective utilization of space. On the Basis of production, designing a new layout may follow different ways such as product, process, mixed, fixed position and group layout. Since yarn is produced in mass production system with a limited variety on a steady demand, product layout is the matter of concern.

This paper is organized as follows. Section 2 gives an overview of relevant literature. In section 3 provides the methodology of SLP procedure. Analysis of original plant layout is shown in section 4. In section 5 original plant layout is analyzed by SLP theory. Proposed layout is shown in section 6. Comparison between proposed and existing layout is shown in section 7. Finally in section 8 shows the resells, conclusion & further work that can be done in this field.

2. II.

3. Literature Review

Many researches have been done in facility planning area. Effective facility planning can reduce significantly the operational costs of a company by 10-30%. Proper analysis of facility layout design could result in the improvement of the performance of production line. This can be realized by optimizing the capacity of a bottleneck; minimizing material handling costs; reducing idle time; maximizing the utilization of labor, equipment and space.

Facility planning is an overall approach concerned with the design, layout and incorporation of people, machines and activities of a system. Huang emphasizes that facility layout design defines how to organize, locate, and distribute the equipment and support activities in a manufacturing facility to accomplish minimization of overall production time, maximization of operational efficiency, growth of revenue and maximization of factory output in conformance with production and strategic goals.

Wiyaratn and A. Watanapa study plant layout of iron manufacturing based on the systematic layout

4. Analysis of Original Plant Layout

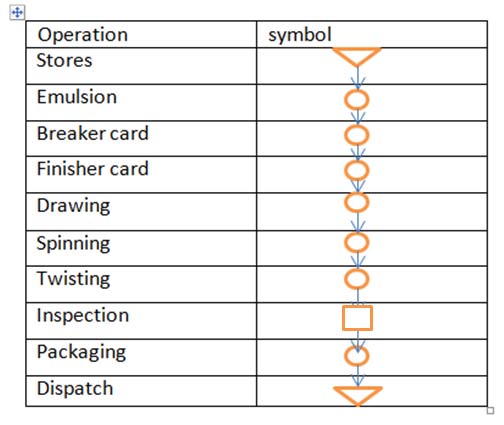

This case is based on the yarn production of jute industry. The original layout of company shown in In this study, the yarn production of standard sizes is mostly analyzed. The operation process flow is shown in Fig. 2. The size of the equipment was relational to the area as shown in Table 1. According to the original plant layout, total working area, distance travelled of materials and unit flow cost and total cost could be discussed as follows:

5. b) Utility of the Area

Total working area is more than equipment area because some spaces are required for the temporal storage of work in process inventory as well as free movement of worker.

c) The Amount and Sequence for Manufacturing In a cycle of yarn production, there produced 100KG of final product. Total cost incurred with production is raw material cost, machining cost, transportation cost and wages. By applying the process of SLP costs related with transportation can be reduced. Statistics shows that per meter transportation cost is 6.75BDT. Our goal is to rearrange the department in such a way that will reduce both travelled distance and transportation cost. V.

6. Analysis Plant Layout based on slp

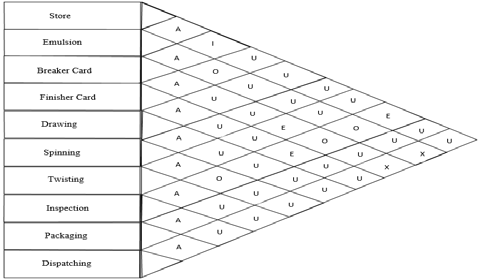

According to the study of the manufacturing process, it was found that the travelled distance should be reduced for moving raw materials and also the useless area should be reduced. It is done by applying SLP method on the existing plant lay out. The result is continuous work flow with a sequential departmental arrangement. Activity relationship chart is used to find the most dependent department based on sequential activity. The activity relationship chart is defined as follows. The reason behind most absolute essential department is continuous flow of material. Beside that sometimes they share common personnel, similar type of supervision, same space or equal opportunity of convenience.

7. Closeness Rating

Rating Definition

8. Analysis of Proposed Layout

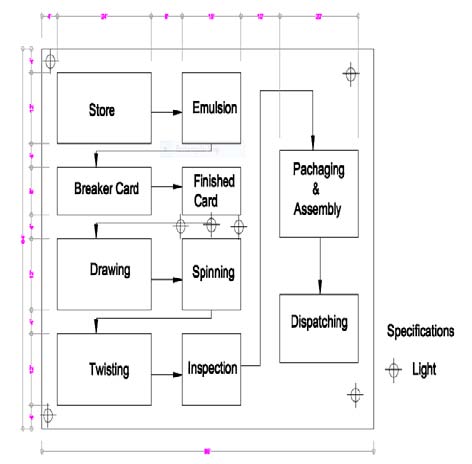

The proposed layout is based on the activity relationship chart and the theme of reducing travelled distance. Altering the positions between several departments will ensure smooth flow of materials as well as it will reduce total travelled distance throughout the production unit. The proposed layout are shown in

9. Result

After analyzing the existing layout it is shown that for a production of 100kg yarn total material handling costs are 1829.25BDT while it is reduced to 1120.5BDT for the modified layout. Implementation of newly developed layout can save 38.75% of total handling costs. It is due to the reduction of the distance between workflow and smooth flow of material throughout the cycle. Therefore rearranging the layout improves material flow, reduced travelled distance and cost resulting in an increase in production.

10. Conclusions & future study

In this paper per unit cost and distance are considered to improve existing layout but there are many other parameters to analyze the layout that may be worker number, area required, equipment required. Due to Lack of opportunity and practical limitations above two parameters are used in our calculation.

The problem of existing layout is large comparative distance between several departments that's forced to travel long distance and impedes the smooth material flow and leads to higher cost.

In our proposed layout the position of various departments are altered with various others based on activity relationship chart.

The machines (Breaker card, Finisher card, Drawing, twisting) used in yarn production are highly weighted. The alternation of those machines are highly costly and time consuming. So, This proposed model will mostly be preferable while setting up a new plant.

| 1 : Relationship between equipment | |||

| size and area | |||

| Department Number of | Equipment | Total | |

| equipment | area | working | |

| ( ft 2 ) | area | ||

| ( ft 2 ) | |||

| Stores | - | - | 180 |

| Emulsion | 1 | 140 | 180 |

| Breaker card | 2 | 160 | 192 |

| Finisher card | 1 | 240 | 288 |

| Drawing | 4 | 240 | 288 |

| Spinning | 2 | 160 | 180 |

| Twisting | 1 | 160 | 180 |

| Inspection | 4 | 100 | 120 |

| Packaging | 2 | 260 | 300 |

| Dispatch | - | - | 240 |

| a) The Flow of Materials | |||

| Raw materials carrying are barely maintained in | |||

| a sequential path | |||

| 2 : Distance and cost incurred | |||

| with present layout | |||

| From | To | Distance | Unit cost |

| (ft.) | (BDT) | ||

| Stores | Emulsion | 23.5 | 158.625 |

| Emulsion | Breaker card | 37.5 | 253.125 |

| Breaker | Finisher card | 23.5 | 158.625 |

| card | |||

| Finisher | Drawing | 37.5 | 253.125 |

| card | |||

| Drawing | Spinning | 23.5 | 158.625 |

| Spinning | Twisting | 39.5 | 266.625 |

| Twisting | Inspection | 23.5 | 158.625 |

| Inspection | Packaging | 45.0 | 303.75 |

| Packaging | Dispatch | 17.5 | 118.125 |

| Total | 1829.25 | ||