1. Introduction

? Induction motor has fractional horse power ratings. They were used in fans, washing machines, drillers, record players, refrigerators, and so on. These motors were simple in construction. But have the drawbacks like lack of starting torque, reduced power factor and efficiency. The efficiency and power factor of the single phase induction motor could be improved by adding nano fillers to the enamel used in these motors. Generally, enamel was used for impregnation, coating and adhesion. This project deals with the coating of windings of the motor with enamel filled with various nano fillers. The efficiency, thermal withstanding capacity, power factor and life time of the motors were improved by using several nano fillers such as Al 2 O 3 , SiO 2 , TiO 2 , ZrO 2 and ZnO and hence these type of single phase induction motors were simply called as Nano motors. These methods of efficiency improvement could be adopted for the various types of motors used in the industrial and house hold appliances. The majority of Single phase motors were of induction type. Hence, various researches were focussed on these types of motors. The motor power rating was always in the terms of fractional HP. Depending upon the starting methods, they were classified into: ? Split phase Induction motor ? Capacitor start Induction motor ? Capacitors run Induction motor ? Capacitor start Capacitor run Induction motor ? Shaded pole Induction motor 1? synchronous motors were used in clocks and turn tables where constant speed was required. 1? synchronous motors were of two types: reluctance and Hysteresis type. 1? series motor was also called as universal motor. These types of motors can operate either in AC or DC supply. These motors were used in kitchen equipment, portable tools and vacuum cleaners where high starting torque and high speed were required. The construction of 1? Induction motor was as similar as 3? squirrel cage motor. The rotor was as same as that of a 3? Induction motor, but the stator has only a single phase distributed winding. It was consists of stator and rotor. The air gap was uniform between stator and rotor. There was no external electrical connection between stator and rotor but they were magnetically coupled with each other by means of the air gap flux. 1? Induction motor was not self starting because it has no self starting torque. This concept was explained by double filed revolving theory and cross field theory. The starting method of 1? Induction motor was very simple. An auxiliary winding was provided in addition to the main winding. 1? Induction motor were used in compressors, pumps, conveyors, refrigerators, air conditioning machines, washing machines, blowers, turn tables, hair driers and so on. 1? Induction motor was having the following demerits: low efficiency, low power factor and very low starting torque. The

2. Proposed Work

Ball mill method was an efficient method used for the preparation of nano fillers due to its availability and ease of operation. Ball mill was used for grinding of micro particles into fine nano particles. When compared to other methods of preparation of nano particles, it was economic. Hence, ball mill method was often used for the preparation of nano particles. Ball mill was also available in all the research institutions also. There were two ways of grinding: dry process and wet process. It was widely used for the manufacture of cement, silicate product glass, ceramics and so on. The micro particles of SiO 2 and Al 2 O 3 were converted into nano particles by this ball mill method only. SEM was one of the mostly used equipment to augment the particle size of the prepared nano filler. SEM was available in various research centres for augmenting the particle size of the nano powders. In this research, for 100 ml of enamel, 5 gm of nano fillers were added. In the 5 gm of nano composites, 1 gm constitutes Al 2 O 3 and 4 gm constitutes SiO 2 . These nano fillers were mixed with the enamel by using ultrasonic vibrator. Then this mixed enamel was coated with the windings of the single phase motor. Depending upon the types and size of winding, production rate, several application methods were adopted during the manufacture of electrical machines. In Dip or Flood Impregnation method preheated winding was slowly dipped in the varnish or resin preferably with the slots in vertical direction. After certain time, the winding was removed from the varnish tank excess varnish was allowed to drip and cured. In a slight variation to this simple dip process, the pre dried winding was kept in a varnish tank and varnish pumped to slowly raise the varnish level till the winding was completely submerged. This was called flood impregnation. One of the limitations of this method was that impregnating agent gets coated on unwanted parts of the winding. Pre dried winding was placed in an impregnant chamber which was then evacuated to very low vacuum for Vacuum or Vacuum-Pressure Impregnation (VPI) Method. The impregnating agent was fed in till complete submersion of winding. For further penetration in compact or fine size wire wound units, dry compressed air or Nitrogen pressure was applied, after breaking vacuum. VPI method was generally employed for electrical machines and coils requiring high quality impregnation. In Trickle Impregnation method, a thin jet of impregnating resin was poured on to preheated & rotating winding, sometimes kept inclined to the horizontal axis. The impregnating resin penetrates through the winding and gets polymerized in a short time. The method offers several advantages such as short processing time, no long post curing, no drain loss, high retention and consistent quality of impregnation. Finishing varnishes were used to give an enveloping coat over the exposed impregnated winding for additional protection against moisture, chemical fumes and dust. Finishing varnish or resin was generally applied by brushing and spraying. Depending upon the type used, the winding was cured at ambient or elevated temperature in an oven. The specification of the single phase motor used for this study was shown in the table 1. Various tests were conducted on the single phase motor to find the efficiency and thermal withstanding capacity of the motor. Load test was conducted to find the performance of the single phase motor whereas Heat run test was conducted to find the thermal withstanding capacity of it. The proposed work was shown in the figure 1.

3. Experimental a) Heat Run Test

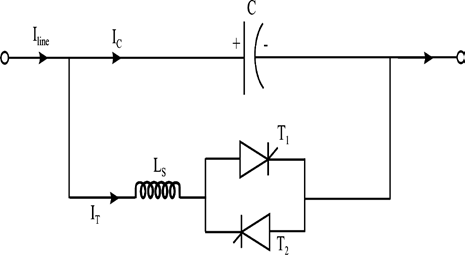

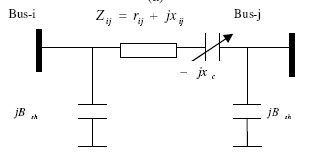

The thermal withstanding capacity of the motor during day time and night time was observed by conducting heat run test. The initial temperature of the motor during day time and night time was noted. Then the time was increased gradually by 5 minutes and the temperature was noted during day time and night time. The table 2 shows the thermal withstanding capacity of both normal single phase motor and nano coated single phase motor during day time and night time. The maximum temperature rise of the normal motor was 63? C during day time whereas that of the nano coated motor was 57? C. The maximum temperature rise of the normal motor was 58? C during night time whereas that of the nano coated motor was 53? C. The temperature of the nano coated motor was decreased by 6? C when compared to that of normal motor during day time. The temperature of the nano coated motor was decreased by 5? C when compared to that of normal motor during night time. The thermal withstanding capacity of the motor was increased by adding nano fillers to the enamel used for coating the windings of the motor. The temperature of the nano coated motor was decreased by 9.5% when compared to that of normal motor during daytime. The temperature of the nano coated motor was decreased by 8.6% when compared to that of normal motor during night time. Figure 2 shows the Comparison of thermal withstanding capacity of various motors during day time and night time. The performance of the single phase induction motor was found by using direct loading. The connections were given as per the circuit diagram shown in the figure 3. The supply was switched on. One set of readings were taken at no load. The load was varied in suitable steps and all the meter readings were noted up to 120% of full load. The load test was conducted during day time and night time and the readings were shown in the table 3 to 6 for both the normal motor and nano coated motor. The different performance curves of the single phase induction motor before and after nano coating were shown in the figure 4 to 15. The maximum efficiency obtained from the single phase induction motor before nano coating was 59.05% during daytime whereas that of the single phase induction motor after nano coating was 78.12%. Similarly the maximum efficiency obtained from the single phase induction motor before nano coating was 57.75% during night time whereas that of the single phase induction motor after nano coating was 70.83%. The efficiency was improved by 19.07% during the daytime by adding nano coating to the single phase induction motor whereas the efficiency was improved by 13.08% during the night time.

4. Conclusions

The following observations were made as clear from this research:

? The temperature of the nano coated motor was decreased by 9.5% when compared to that of normal motor during daytime. The temperature of the nano coated motor was decreased by 8.6% when compared to that of normal motor during night time.

? The efficiency was improved by 19.07% during the daytime by adding nano coating to the single phase induction motor whereas the efficiency was improved by 13.08% during the night time.

V.

| Motor Type | Capacitor run Induction |

| Motor | |

| Phase | 1? |

| Capacity | ¼ HP |

| Rated voltage of motor | 230 V |

| Rated current of motor | 2.5 A |

| Frequency | 50 Hz |

| No of poles | 4 |

| Synchronous Speed of the | 1500rpm |

| Motor | |

| Capacitor value | 10 µF |

| Insulation | Class B |

| Time in | Normal Motor | Nano coated | Normal Motor | Nano coated |

| min. | Temperature in | Motor | Temperature in | Motor |

| ?C (Day Time) | Temperature in ?C | ?C (Night Time) | Temperature in | |

| (Day Time) | ?C (Night Time) | |||

| 0 | 46.3 | 36 | 38 | 30 |

| 5 | 49.1 | 38 | 39 | 34.5 |

| 10 | 51.5 | 39 | 41 | 39 |

| 15 | 52.7 | 41 | 45.5 | 44 |

| 20 | 54 | 45.5 | 51 | 46 |

| 25 | 55.5 | 51 | 54 | 49 |

| 30 | 57.2 | 54 | 56 | 51 |

| 35 | 59 | 56 | 57 | 52 |

| 40 | 63 | 57 | 58 | 53 |

| S. No | Voltage (volts) | Current (Amps) | Input Power (Watts) | Spring Balance | Speed ( |

| S 1 | S 2 | ||||||||||

| 1 | 230 | 1.25 | 120 | 0 | 0 | 1484 | 0 | 0 | 0.417 | 1.06 | 0 |

| 2 | 230 | 1.4 | 220 | 1 | 2 | 1430 | 0.56 | 83.86 | 0.683 | 4.67 | 38.12 |

| 3 | 228 | 1.5 | 240 | 1 | 2.5 | 1410 | 0.84 | 124.03 | 0.701 | 6 | 51.68 |

| 4 | 228 | 1.7 | 310 | 1.5 | 3.5 | 1348 | 1.12 | 158.10 | 0.799 | 10.1 | 51 |

| 5 | 226 | 1.85 | 340 | 1.5 | 4 | 1328 | 1.40 | 194.69 | 0.813 | 11.4 | 57.26 |

| 6 | 226 | 2 | 390 | 1.5 | 4.5 | 1309 | 1.68 | 230.29 | 0.863 | 12.7 | 59.05 |

| S. No | Voltage (volts) | Current (Amps) | Input Power (Watts) | Spring Balance S 1 S 2 | Speed (rpm) | Torque (N-m) | Output Power (Watts) | Power Factor | Slip (%) | Efficiency (%) | |

| 1 | 214 | 1.05 | 100 | 0 | 0 | 1480 | 0 | 0 | 0.455 | 1.33 | 0 |

| 2 | 216 | 1.2 | 180 | 1 | 1.5 | 1442 | 0.28 | 42.3 | 0.694 | 3.86 | 23.5 |

| 3 | 218 | 1.4 | 220 | 1.5 | 2.5 | 1412 | 0.56 | 82.8 | 0.721 | 5.86 | 37.64 |

| 4 | 218 | 1.6 | 280 | 1.5 | 3 | 1360 | 0.84 | 119.63 | 0.803 | 9.33 | 42.73 |

| 5 | 218 | 1.8 | 350 | 1.5 | 4 | 1342 | 1.4 | 196.75 | 0.892 | 10.53 | 56.21 |

| 6 | 218 | 2.0 | 390 | 1.5 | 4.5 | 1280 | 1.68 | 225.2 | 0.894 | 14.66 | 57.74 |

| 7 | 218 | 2.1 | 400 | 2 | 5 | 1228 | 1.68 | 216.04 | 0.873 | 18.13 | 54.01 |

| 8 | 218 | 2.2 | 420 | 2.5 | 5.5 | 1196 | 1.68 | 210.41 | 0.876 | 20.26 | 50 |

| ( ) F Volume XIV Issue VI Version | |||||||||||

| Global Journal of Researches in Engineering | |||||||||||

| S. No | Voltage (volts) | Current (Amps) | Input Power (Watts) | Spring Balance S 1 S 2 | Speed (rpm) | Torque (N-m) | Output Power (Watts) | Power Factor | Slip (%) | Efficiency (%) | |

| 1 | 218 | 1.05 | 100 | 0 | 0 | 1488 | 0 | 0 | 0.436 | 0.8 | 0 |

| 2 | 218 | 1.2 | 190 | 0.5 | 1.5 | 1436 | 0.56 | 84.21 | 0.726 | 4.27 | 44.32 |

| 3 | 218 | 1.45 | 240 | 0.5 | 2.5 | 1392 | 1.12 | 163.26 | 0.786 | 7.2 | 68.03 |

| 4 | 216 | 1.6 | 270 | 1 | 3.5 | 1360 | 1.4 | 199.39 | 0.781 | 9.3 | 73.85 |

| S. No | Voltage (volts) | Current (Amps) | Input Power (Watts) | Spring Balance S 1 S 2 | Speed (rpm) | Torque (N-m) | Output Power (Watts) | Power Factor | Slip (%) | Efficiency (%) | |

| 1 | 218 | 1 | 110 | 0 | 0 | 1482 | 0 | 0 | 0.504 | 0.06 | 0 |

| 2 | 218 | 1.15 | 170 | 0.5 | 1.5 | 1436 | 0.559 | 84.06 | 0.678 | 4.2 | 49.45 |

| 3 | 218 | 1.3 | 210 | 0.5 | 2 | 1420 | 0.838 | 124.61 | 0.741 | 5.33 | 59.34 |

| 4 | 218 | 1.5 | 240 | 1 | 2.5 | 1396 | 0.838 | 122.51 | 0.733 | 6.93 | 51.04 |

| 5 | 218 | 1.75 | 320 | 1 | 3.5 | 1352 | 1.397 | 197.79 | 0.838 | 9.86 | 61.81 |

| 6 | 218 | 1.9 | 360 | 1.5 | 4.5 | 1310 | 1.677 | 230.1 | 0.869 | 12.6 | 63.92 |

| 7 | 218 | 2 | 390 | 1.5 | 5 | 1282 | 1.96 | 263.13 | 0.894 | 14.5 | 67.46 |

| 8 | 221 | 2.25 | 410 | 1.5 | 5.5 | 1238 | 2.24 | 290.4 | 0.824 | 17.4 | 70.83 |